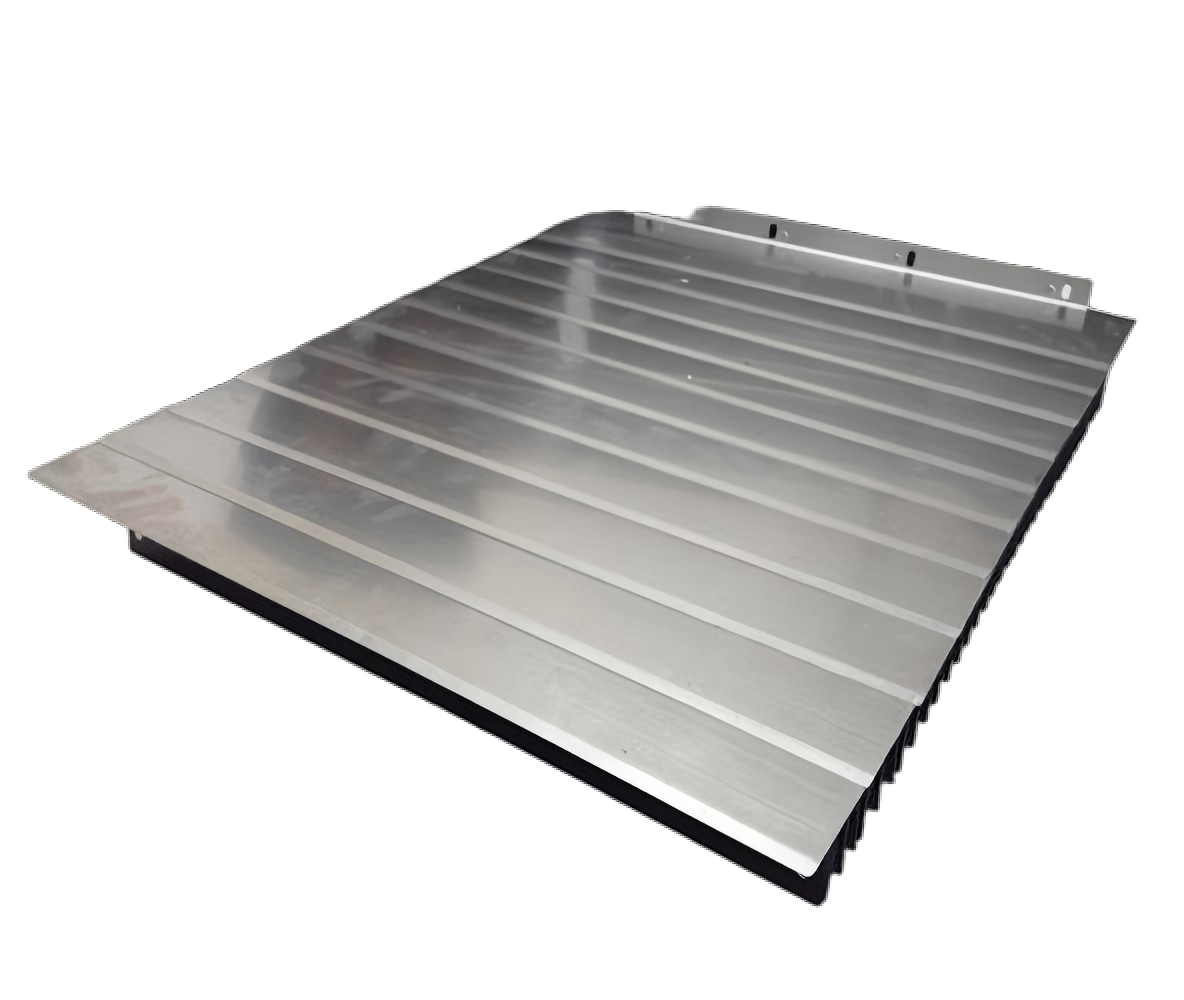

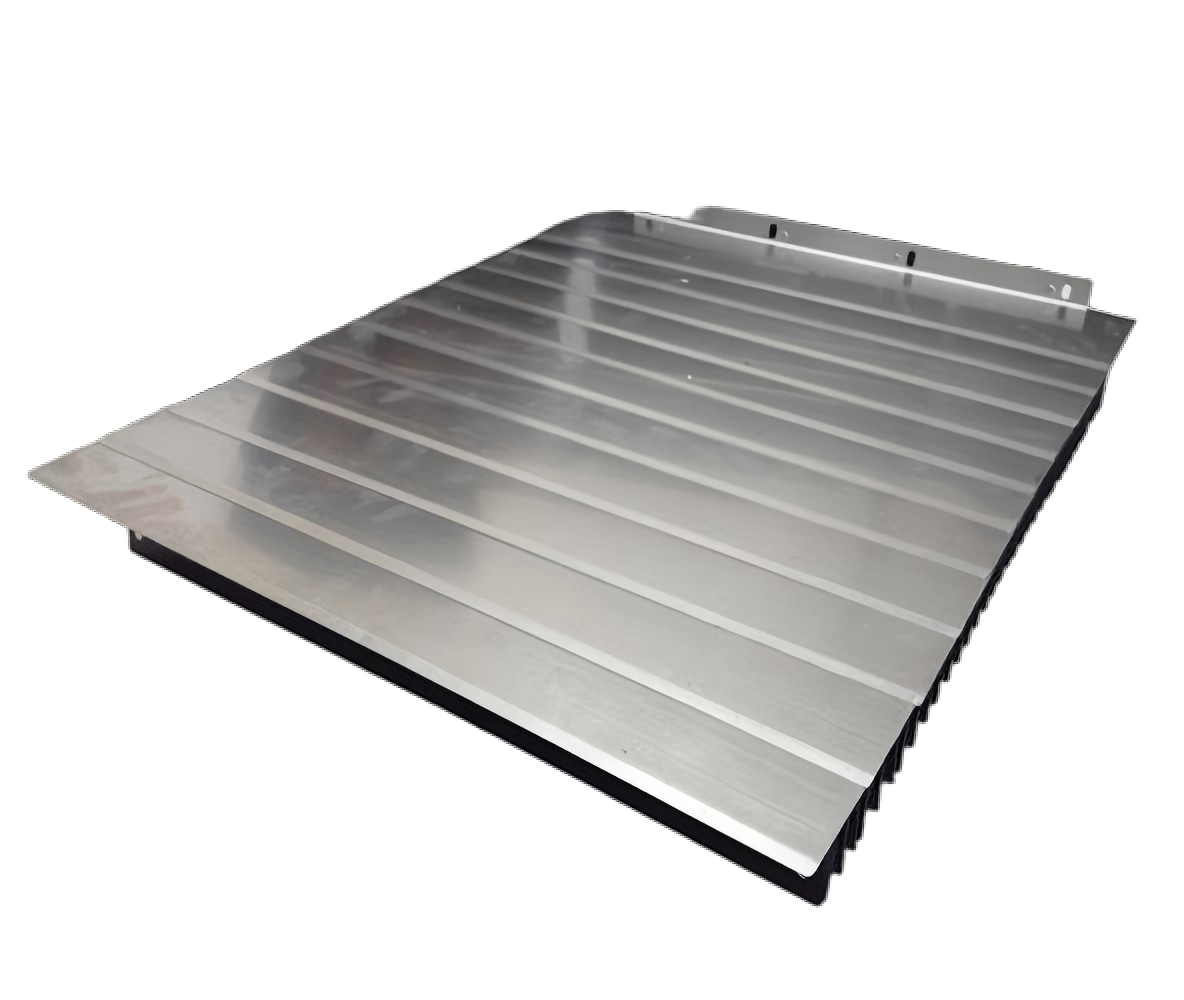

Stainless steel protective cover welding

Welding quality directly impacts product reputation! Many manufacturing companies, when upgrading their products and targeting high-end customers, hope to find equipment that can achieve "seamless welding" and consistent quality.

In the case study shared today, a company specializing in the production of machine tool auxiliary equipment chose the PDKJ platform-type seamless laser welding machine, elevating their product quality to a new level and winning more high-quality orders.

I. Project Background

The Dongguan-based client in this collaboration has been deeply involved in the field of machine tool protection equipment for many years. It is a professional enterprise integrating design, production, sales, and service. Their product system is rich and comprehensive, covering sheet metal telescopic covers, flexible bellows protective covers, machine tool enclosures, chip conveyors, plastic cable carriers, and a series of other machine tool auxiliary equipment. They can meet the machine tool protection needs of different models and scenarios, and have long provided supporting services to machine tool manufacturers in the Pearl River Delta and throughout China, thanks to their mature technology and reliable service.

As market demands for the precision, appearance, and durability of machine tool protection equipment continue to increase, the client planned to expand its high-end customized business – providing higher-quality protective products to meet the personalized needs of high-precision machine tool customers. Although their previously used welding equipment could meet basic production requirements, it failed to meet the "seamless appearance, precise fit, and multi-scenario compatibility" required for high-end orders.

To break through product quality limitations and meet the stringent standards of the high-end market, the client decided to introduce more advanced welding technology. After extensive research and sample testing, they ultimately chose to collaborate with PDKJ, adopting a platform-based seamless laser welding machine to empower the welding process upgrade for their entire range of protective products.

II. Client's Production and Welding Requirements

To uphold their quality policy of "meeting user needs," the client put forward clear and rigorous requirements for the welding of stainless steel protective cover slides:

Quality Standards: The weld seam surface must be flat, with no marks or indentations on the back. The weld seam must have excellent bonding strength with the base material, ensuring that the slide will not crack during long-term use;

Ease of Operation: The equipment must be easy to use and adjust, capable of quickly integrating into the existing production line, reducing reliance on experienced welders, and ensuring consistent product quality across different batches;

Multi-functional Adaptability: In addition to stainless steel protective cover slides, the equipment must also be compatible with welding other metal components such as protective cover housings and brackets, increasing equipment utilization, reducing overall investment costs, and matching the company's diversified product system;

III. Highlights and Advantages of the PDKJ Welding Machine

Addressing the diverse product characteristics and high-end development needs of its customers, the PDKJ team, combining the thin-material properties of the stainless steel protective cover and slide rail with key welding process requirements, conducted multiple rounds of prototyping and solution optimization. They ultimately determined that a 2000W platform-type seamless laser welding machine would be the core solution. Thanks to the equipment's high performance and adaptability to various scenarios, it precisely meets production requirements:

1. Seamless Precision Welding, Empowering High-End Quality

The core advantage of the PDKJ platform-type seamless laser welding machine lies in its "seamless + high precision" capabilities, perfectly matching customers' pursuit of high-end quality. During the welding process, the laser energy is concentrated and the heat-affected zone is extremely small, resulting in smooth and even welds with minimal spatter on the front and no marks on the back. This completely eliminates the appearance defects of traditional welding, allowing products such as protective covers and door panels to present a refined texture without additional processing, directly increasing product added value. At the same time, precise welding control effectively avoids sheet metal deformation, ensuring the dimensional accuracy of various protective components and guaranteeing smooth assembly and stable use, fully meeting the quality requirements of high-end customers.

2. Comprehensive Adaptability, Covering Diverse Products

The equipment adopts a flexible "platform + swing arm" structure, coupled with an adjustable dual-axis handheld welding gun, easily handling welding scenarios for the customer's entire product range. The swing arm welding range covers the entire platform, and with movable casters, the equipment can be flexibly positioned without frequent workpiece movement – whether it's continuous welding of long stainless steel protective cover slides, flat welding of large-area sheet metal protective covers, or precise spot welding of small cover brackets and chip conveyor metal connectors, it achieves seamless, high-precision welding without blind spots.

3. Convenient and Easy to Use, Ensuring Welding Consistency

The equipment is simple and intuitive to operate, equipped with a clear Chinese operation interface and parameter storage function, allowing the customer's technical team to quickly get started without complex training. For the personalized specifications of high-end customized orders, simply recall preset parameters or make simple adjustments with a single click to quickly switch welding schemes, eliminating the need for lengthy downtime for debugging. This perfectly supports the customer's "rapid response, efficient delivery" customized service model. At the same time, the equipment runs stably and reliably, ensuring consistent welding quality and guaranteeing that every customized product meets high-end standards, helping customers establish a good reputation in the high-end market.

4. Stable and Durable, Ensuring Long-Term Production

The platform-type seamless laser welding machine utilizes high-quality core components and a mature control system, ensuring stable operation and a low failure rate. It is suitable for customers' large-scale production and long-term operation needs. The equipment is compatible with various metal materials such as stainless steel, aluminum, carbon steel, and galvanized steel, not only meeting the current welding needs of various protective products but also providing technical support for customers to expand into new product categories in the future, empowering the long-term development of the enterprise.

IV. Win-Win Cooperation: Make Metal Welding Easy for the World

Currently, the PDKJ platform-based seamless laser welding machine is operating stably in the customer's workshop, becoming a core piece of equipment for their high-end customized business and full range of product production.

Thanks to the seamless welding effect of the equipment, the customer's sheet metal covers, bellows protective covers, and other products have achieved a qualitative leap in appearance and precision, successfully entering the high-end machine tool supporting market and winning long-term cooperation orders from several high-precision machine tool companies.

This collaboration is another successful example of PDKJ's "customer-centric" approach and a remarkable demonstration of its platform-based, seamless laser welding machine in diverse production scenarios.

As a company focused on the research, development, and manufacturing of welding equipment, PDKJ has always been committed to the mission of "Making Metal Welding Easy for the World," while also catering to the individualized needs of different customers. Whether it's standardized equipment directly adaptable to conventional production or customized solutions for specific scenarios, PDKJ responds to industry demands with professional technology. In the future, PDKJ will continue to deepen its innovation in welding technology, providing higher-quality products and services to customers in fields such as rail transit, electrical equipment, and metal fabrication, empowering high-quality industrial development with efficient welding technology.

Purchase Invitation

If you are struggling with welding issues for products such as vehicle interior components, sheet metal telescopic covers, machine tool housings, flexible bellows protective covers, seat brackets, electrical equipment enclosures, metal chassis, and reinforced door panels, please contact Guangdong Pudong Automation Technology Co., Ltd. immediately. Our professional technical team, high-quality welding equipment, and comprehensive service system will provide you with the most suitable welding solutions. Let PDKJ be your reliable partner in welding, helping you overcome welding challenges, improve product quality and production efficiency, and contribute to the thriving development of your business. PDKJ, your welding expert, looks forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713