Delivery Case of PDKJ Special Aircraft

Recently, PDKJ has delivered a "Gantry Spot Welding Machine for Door Panel Reinforcing Ribs" to a customer in the hardware sheet metal industry in Dongguan. With a gantry structure, dedicated fixtures, and automated overall welding, the machine boasts high product yield, fast speed, accurate positioning, and strong rigidity. It addresses issues like large post - welding marks and operational difficulties, offering the hardware sheet metal industry an efficient, automated welding solution. This helps enterprises overcome traditional welding process bottlenecks and achieve a dual improvement in production efficiency and product quality.

1、Customer and Project Background

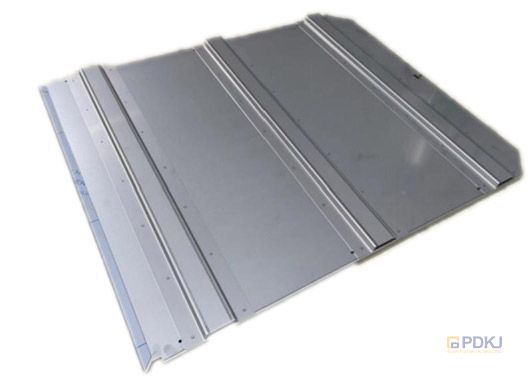

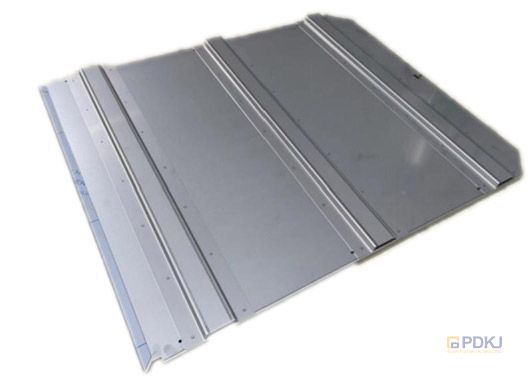

A hardware sheet metal company in Dongguan encountered traditional process bottlenecks in door panel reinforcing rib welding:

- The workpiece is too large for easy positioning and accurate weld point location.

- Manual spot welding is inefficient, taking over 20 minutes per door panel, with poor weld point consistency and appearance, falling short of premium clients' aesthetic and strength requirements.

- The thin welding material demands high precision in welding machine current control to avoid burn - through.

- Conventional welding machines leave large post - welding marks on the product surface, failing to meet requirements.

Faced with these welding challenges, the company urgently sought an automated welding solution to enhance quality and efficiency.

PDKJ, after thoroughly understanding the customer's needs, quickly responded with its deep technical reserves and rich industry experience in welding automation. It customized the “Gantry Spot Welding Machine for Door Panel Reinforcing Ribs” to create an efficient, stable, and precise welding system for the customer.

2、Highlights of Customized Welding Machine Equipment

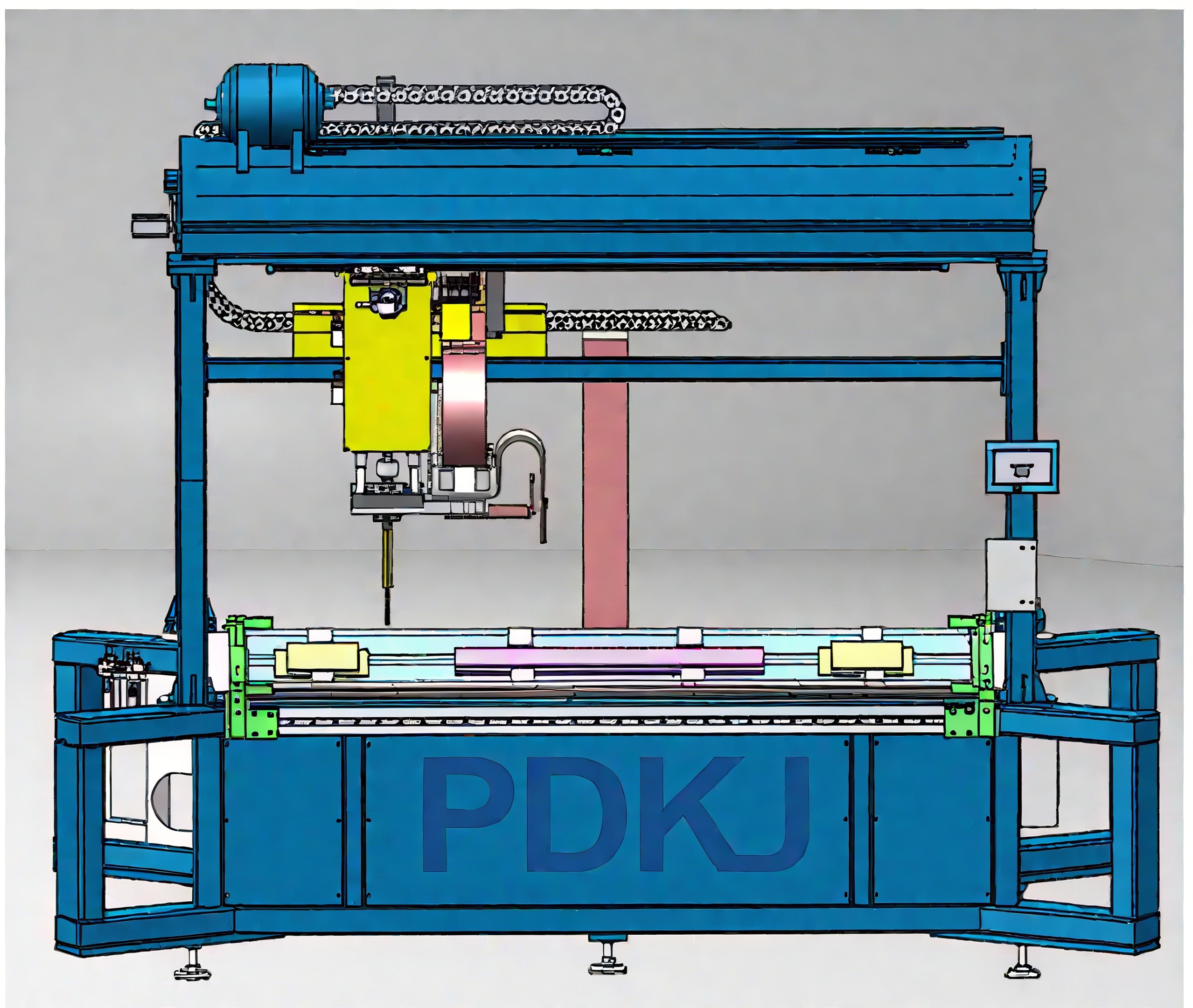

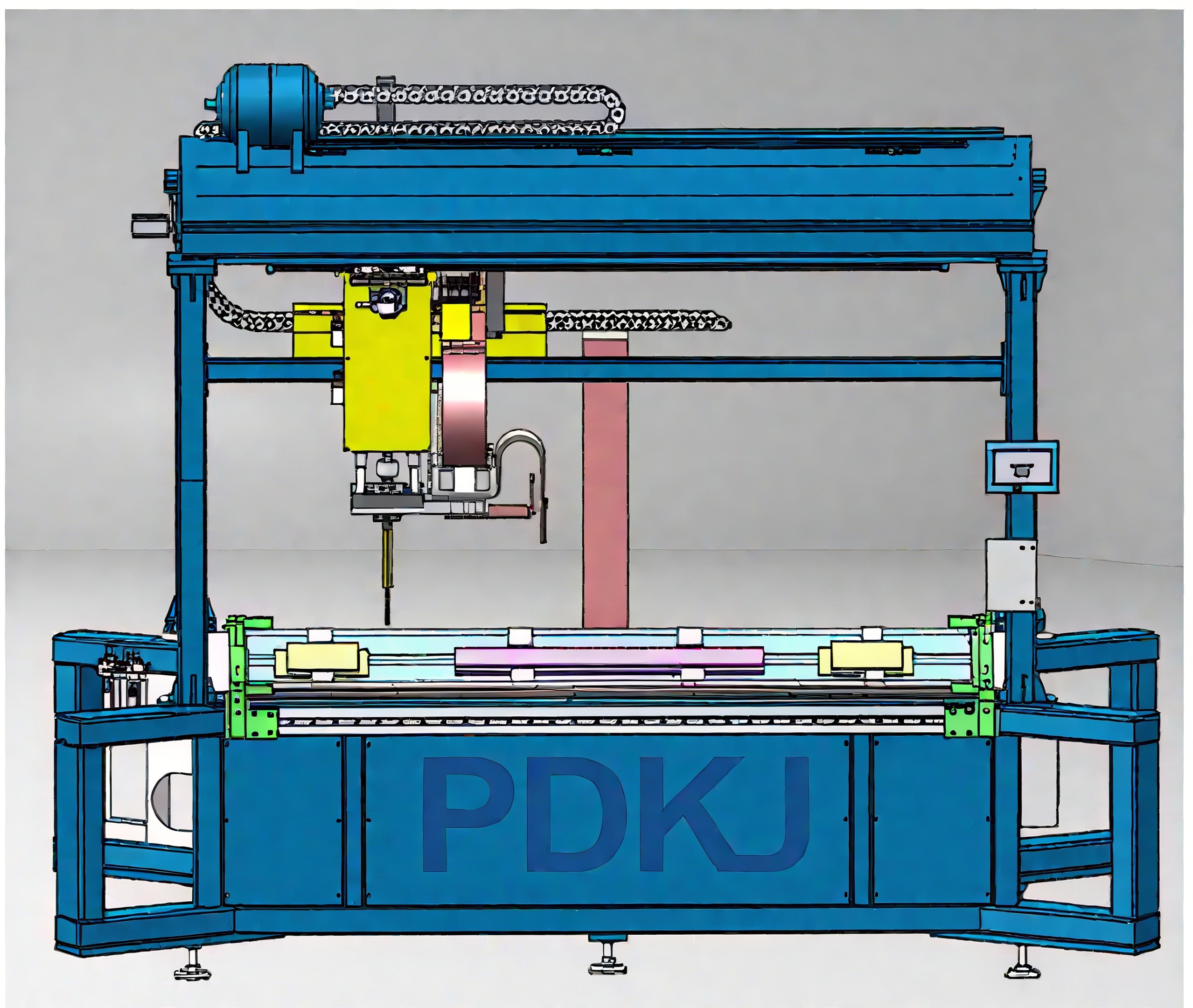

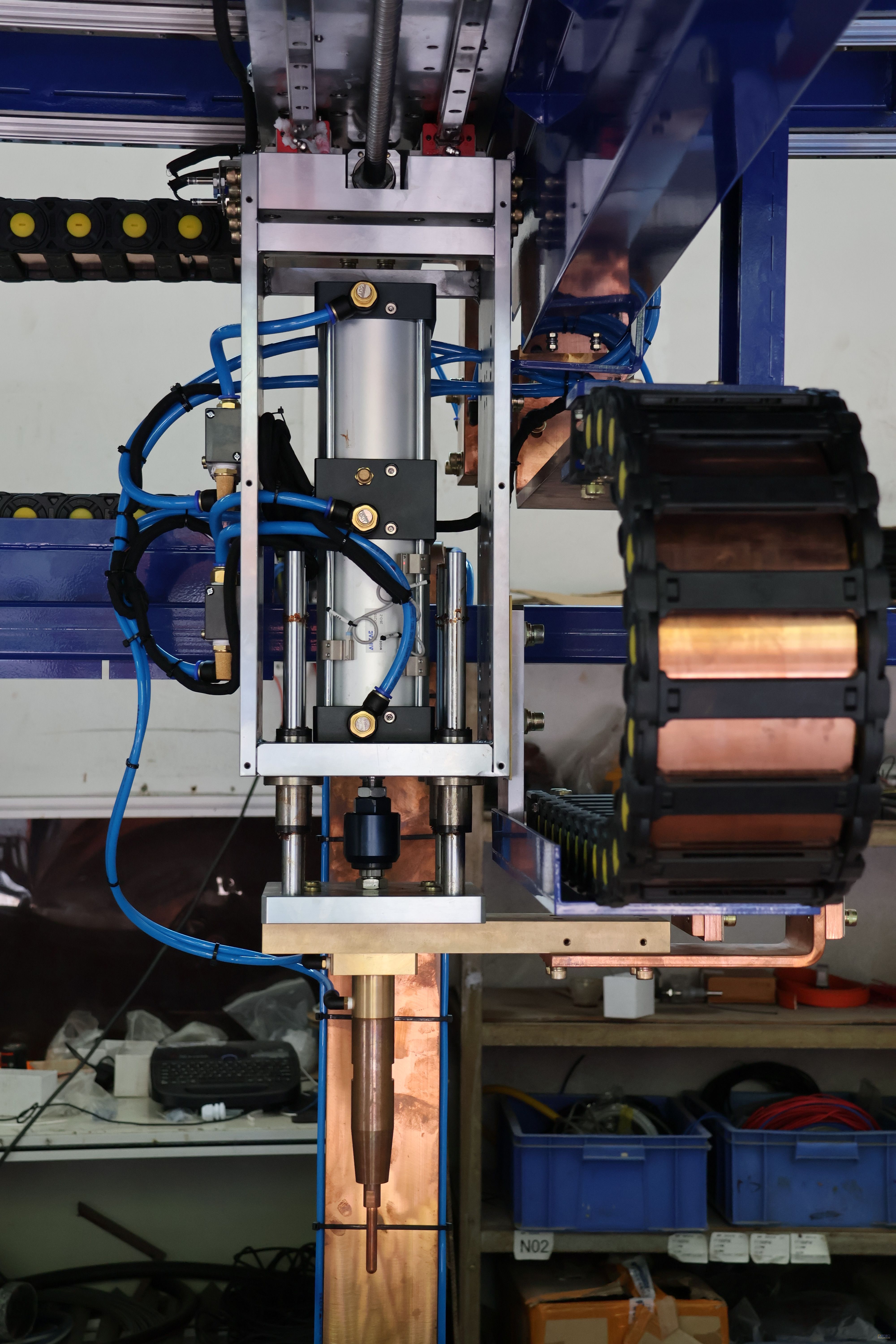

The PDKJ “Gantry Automatic Spot Welding Machine for Door Panel Reinforcing Ribs” meets the hardware sheet metal industry's strict welding equipment requirements and propels process upgrades:

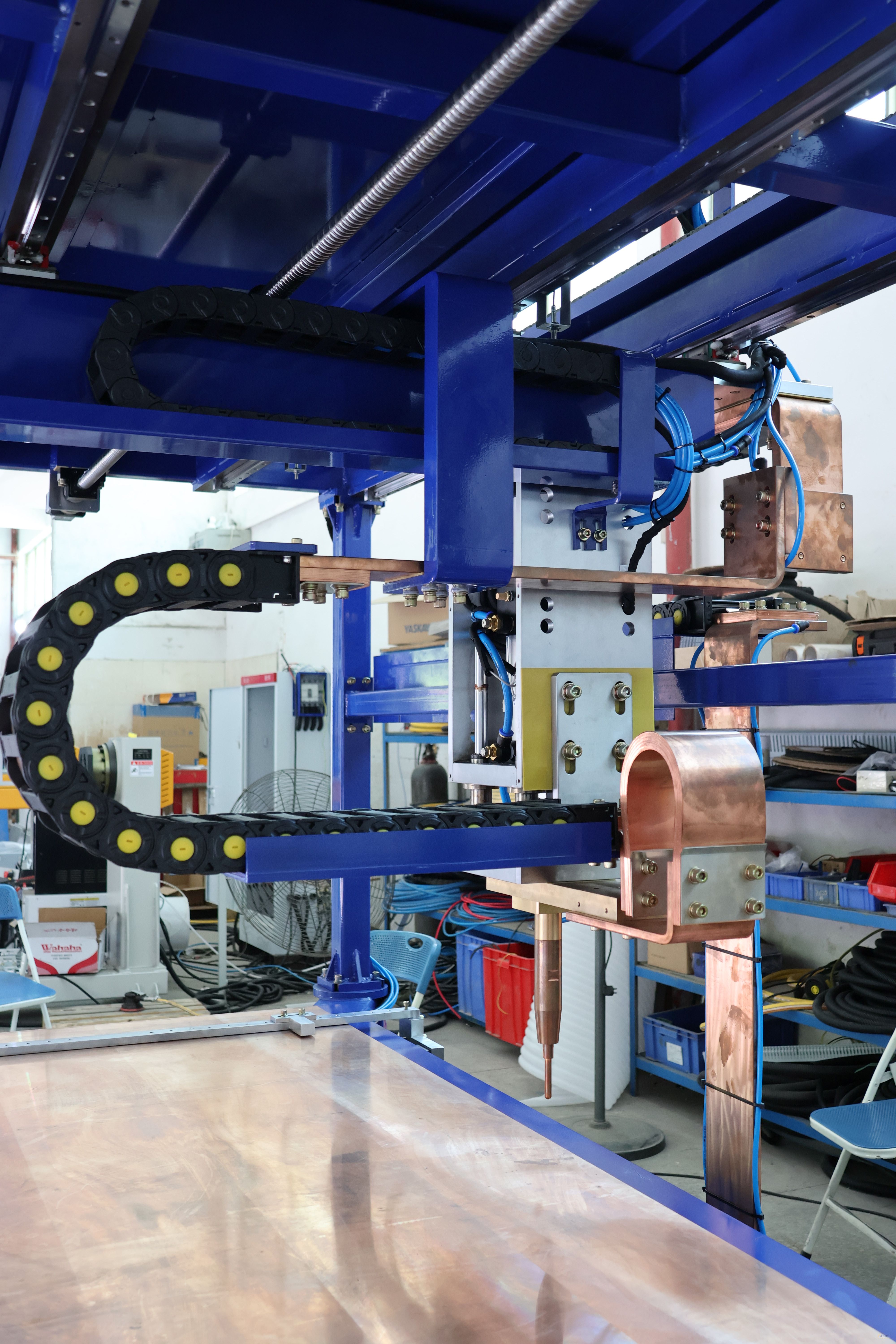

1. Gantry Welding Platform: Ultra - stable, it ensures precise positioning even for large door panels, guaranteeing high - accuracy welding and high - quality weld points.

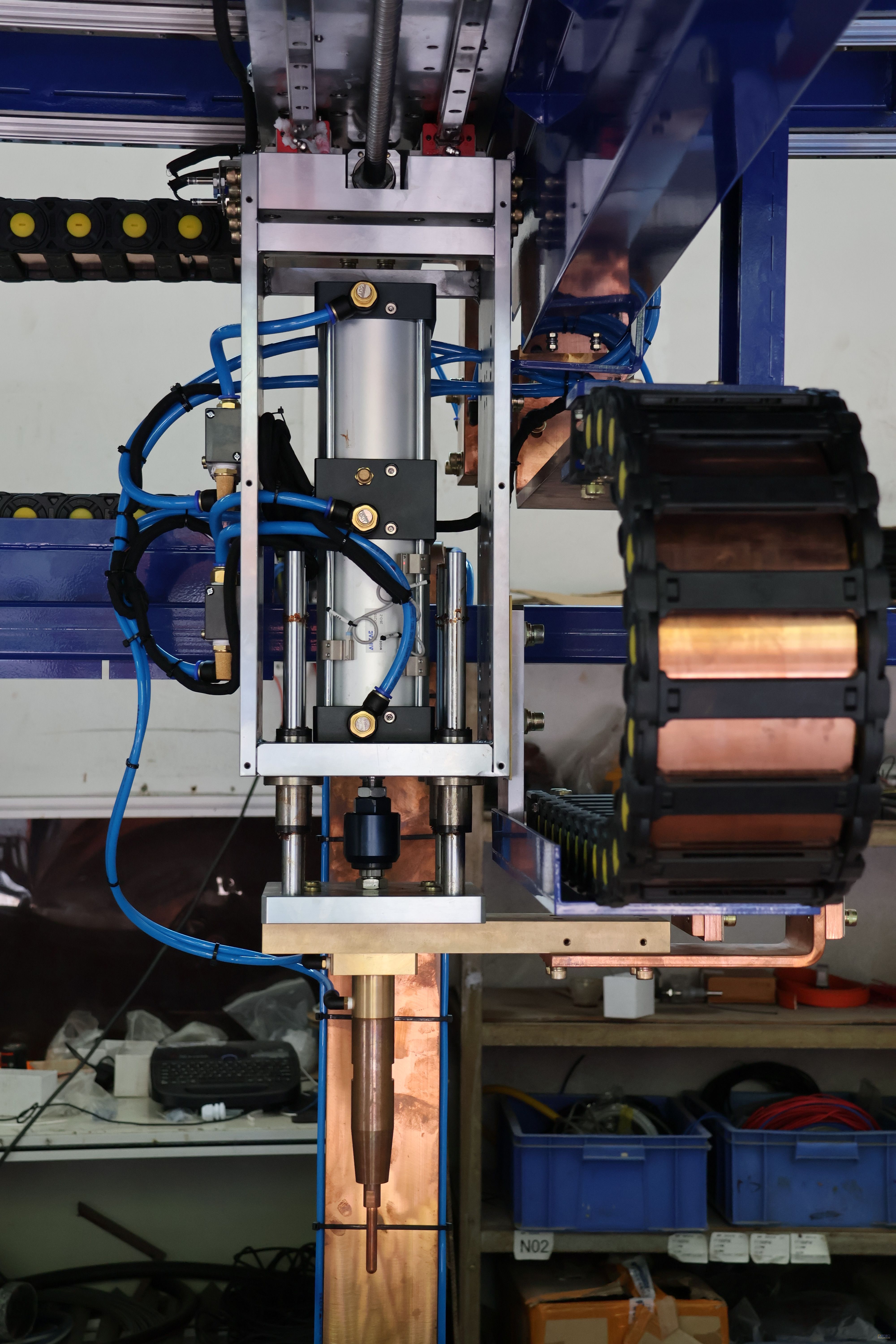

2. XY Dual - axis Moving Welding Head: A highlight, it moves as programmed to automatically weld door panel reinforcing ribs point by point. It's easy to operate, reduces staff workload, ensures even and aesthetic weld point distribution, and boosts welding efficiency for higher output.

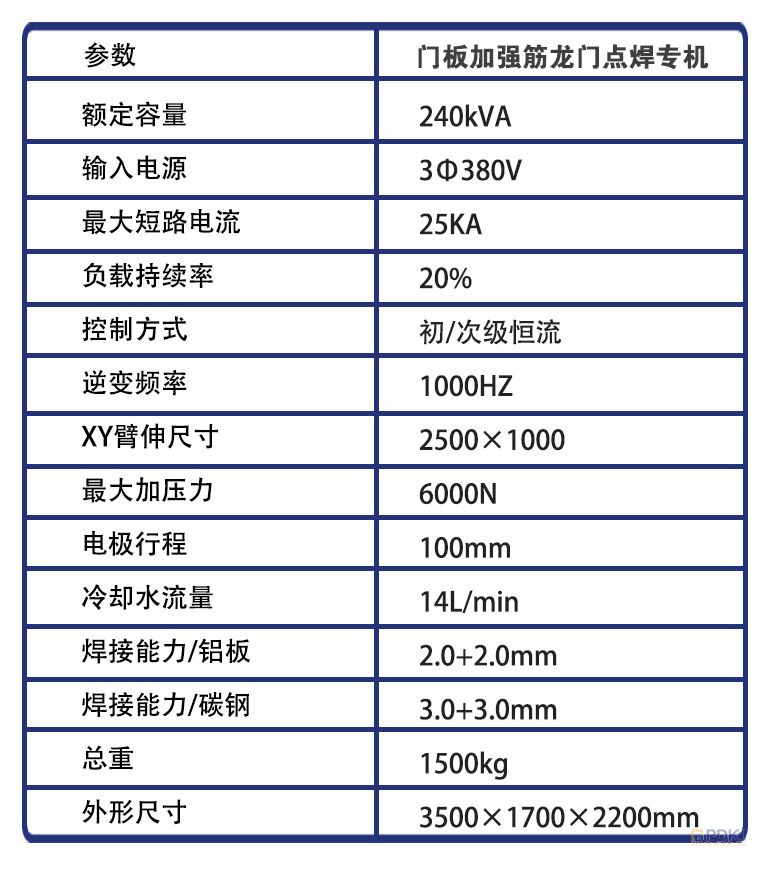

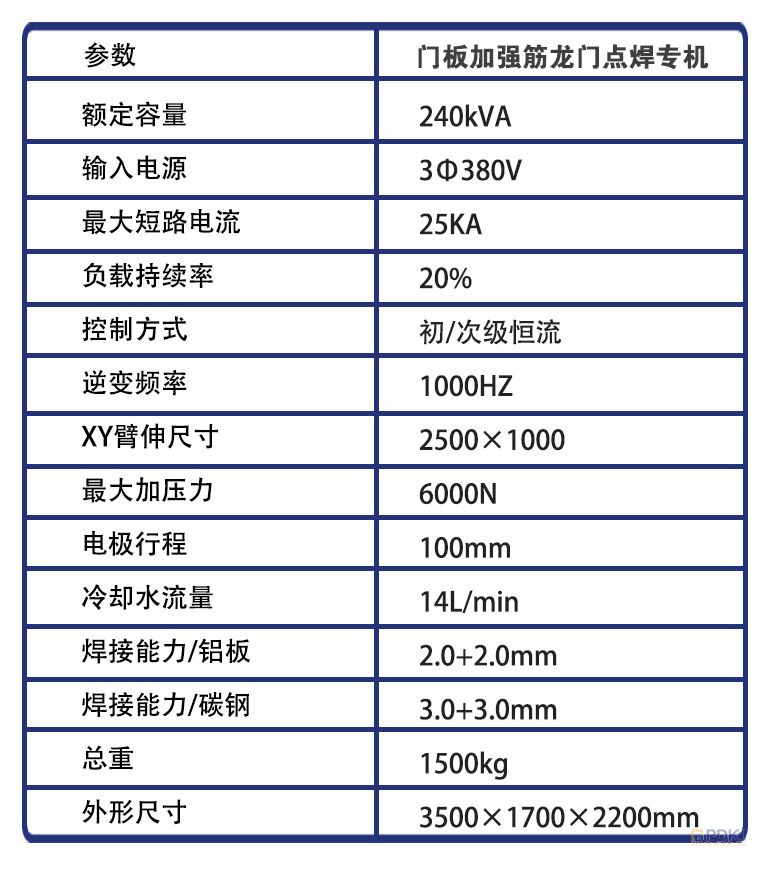

3. Versatile Materials and Thicknesses: With 240kVA rated capacity and 25KA maximum short - circuit current, it handles various high - strength tasks. It can weld aluminum plates up to 2.0mm+2.0mm and carbon steel up to 3.0mm+3.0mm, meeting diverse industry needs and reducing costs.

Welding machine parameters

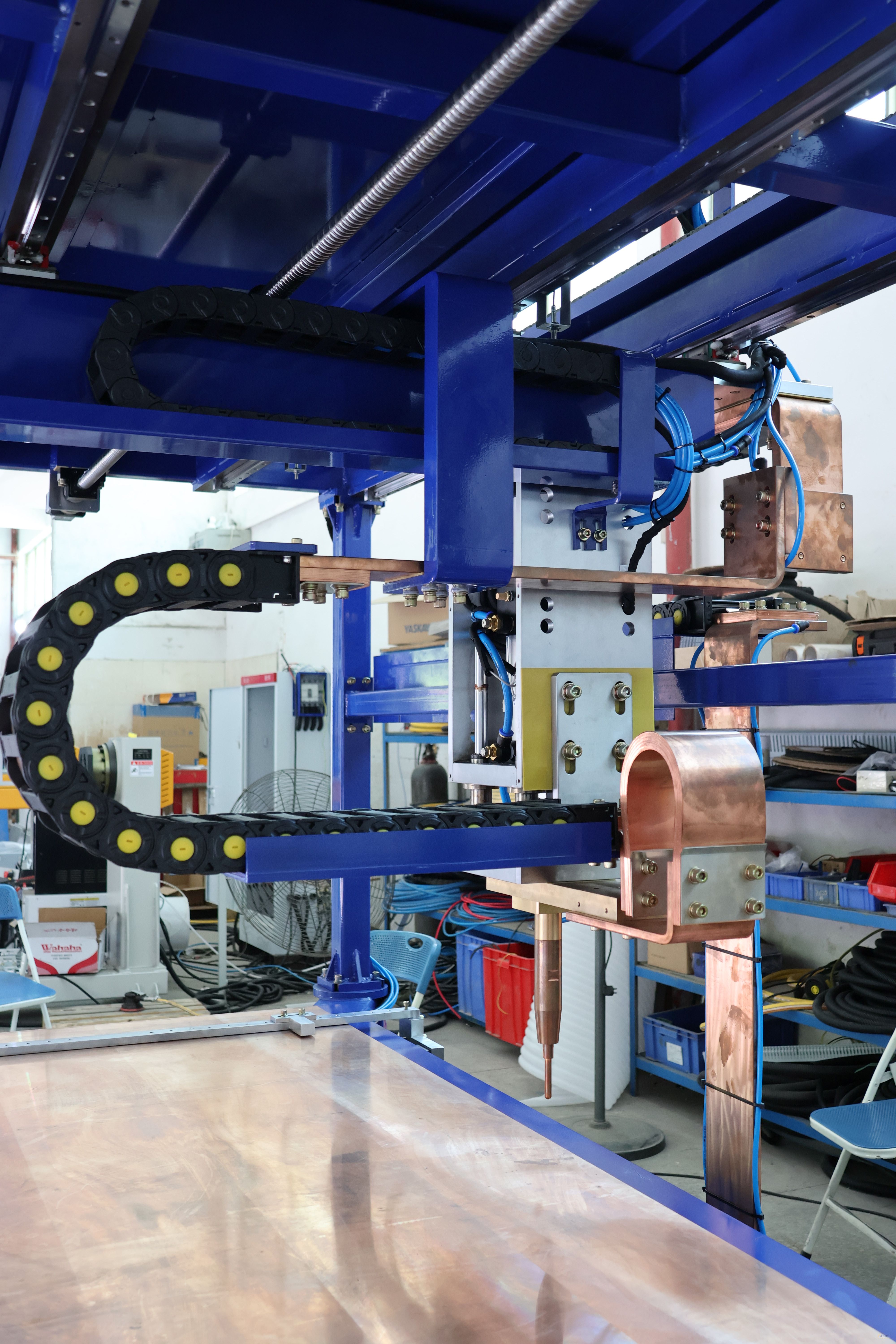

3、Successfully shipped

At PDKJ's shipping site, the “Gantry Spot Welding Machine for Door Panel Reinforcing Ribs” is strictly inspected, debugged, and “armored” before heading to Dongguan hardware sheet metal workshops. Upon arrival, PDKJ technicians install and fine - tune it for optimal production.

The successful delivery of this machine solve welding problems for Dongguan hardware sheet metal customers and upgrades their welding processes with solid performance.

In the future, PDKJ will focus on customer needs and challenges in the hardware sheet metal industry, increase R&D investment, and optimize product performance and services. It will also expand its business to explore more welding application scenarios, contributing to intelligent welding production in multiple industries like hardware sheet metal, rail transit, aerospace, and automobile manufacturing.

PDKJ, committed to its mission of “making no metal products difficult to weld”, explores welding automation, constantly innovating to offer more efficient, smarter, and more reliable welding solutions for the manufacturing sector.

Unlock new possibilities for sheet metal welding immediately

If you have automation welding needs for hardware sheet metal parts like door panel reinforcing ribs or cabinet frames, or require customized non - standard welding equipment, PDKJ provides full - cycle services from process design to equipment delivery.

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713