Delivery Case of PDKJ Special Aircraft

Recently, PDKJ delivered a "CNC Automatic Stud Laser Welding Machine" to a Hefei rail transit industry customer, offering an efficient and intelligent solution for batch welding of studs on rail transit metal components.

1.Customer and Project Background

As a key player in China's rail transit industry, a Hefei-based rail transit equipment manufacturer is dedicated to offering safe and reliable products. Yet, with growing market demands, its original welding process fell short in multiple ways: manual welding couldn't meet mass production needs, welding quality was unstable with significant variations in stud welding strength, leading to high defect rates, and the low automation level hindered integration with automated production lines, becoming a bottleneck for capacity growth. The company urgently sought a solution to enhance welding strength.

Upon learning of the customer's needs, PDKJ swiftly formed a team of experts in technology, process, and service. They delved into the customer's production site to fully understand its processes, product features, and process requirements. PDKJ then tailored a "CNC Three - Gun Automated Stud Welding Machine" solution, helping the customer overcome production challenges and achieve intelligent upgrading.

2.Highlights of Customized Welding Machine Equipment

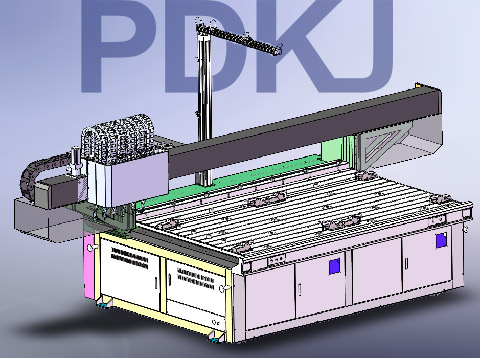

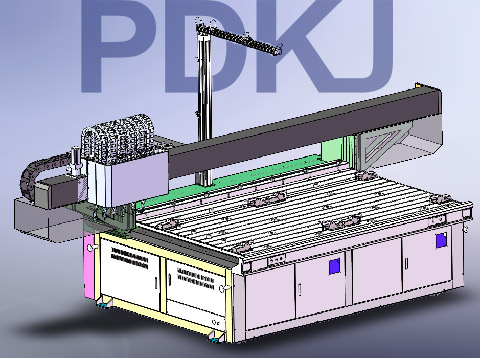

Targeting the rail transit industry's exacting demands for welding equipment—high precision, efficiency, and reliability—PDKJ has crafted a customized CNC automated stud laser welding machine. This machine, integrating multiple innovative technologies, comprehensively addresses traditional welding challenges.

1. Full - process automation: With a gantry - type machine tool structure and multi - axis servo drive system, it seamlessly integrates into automated production lines. It enables unmanned operations from material loading to positioning, welding, and unloading, breaking the efficiency limits of manual welding.

2. High - precision welding: Using 3 - axis CNC, it has a repeatable positioning accuracy of ±0.02mm and welding accuracy within ±0.15mm. This ensures 100% compliance with stud welding strength standards, meeting customers' stringent welding requirements.

3. Strong compatibility and efficiency: It supports M3 - M8 studs (customizable for larger sizes) and works with various metal substrates like cold - rolled steel, stainless steel, and aluminum. With flexible gun configuration (3 - 6 guns标配), it can switch welding modes smartly for different workpieces. Welding speed is 20 - 35 studs/minute, with no marks on the reverse side of the sheet. It can operate continuously for 24 hours, ensuring high - quality and efficient welding.

4. Zinc - layer removal capability: It quickly removes zinc layers, shortens processing time, and improves efficiency. Precise cleaning - area positioning prevents damage to non - cleaning areas, ensures workpiece dimensional accuracy, and avoids mechanical stress and deformation. It's eco - friendly, requires no chemical solvents, suits different workpiece shapes and materials, and connects seamlessly with CNC systems for automated, intelligent production.

5. Smart production management: Equipped with digital communication energy - storage welding machines and an automatic nail - feeding system, it monitors welding parameters (e.g., current, pressure) in real - time and supports multi - gun collaborative operations. This significantly reduces labor costs and the risk of errors.

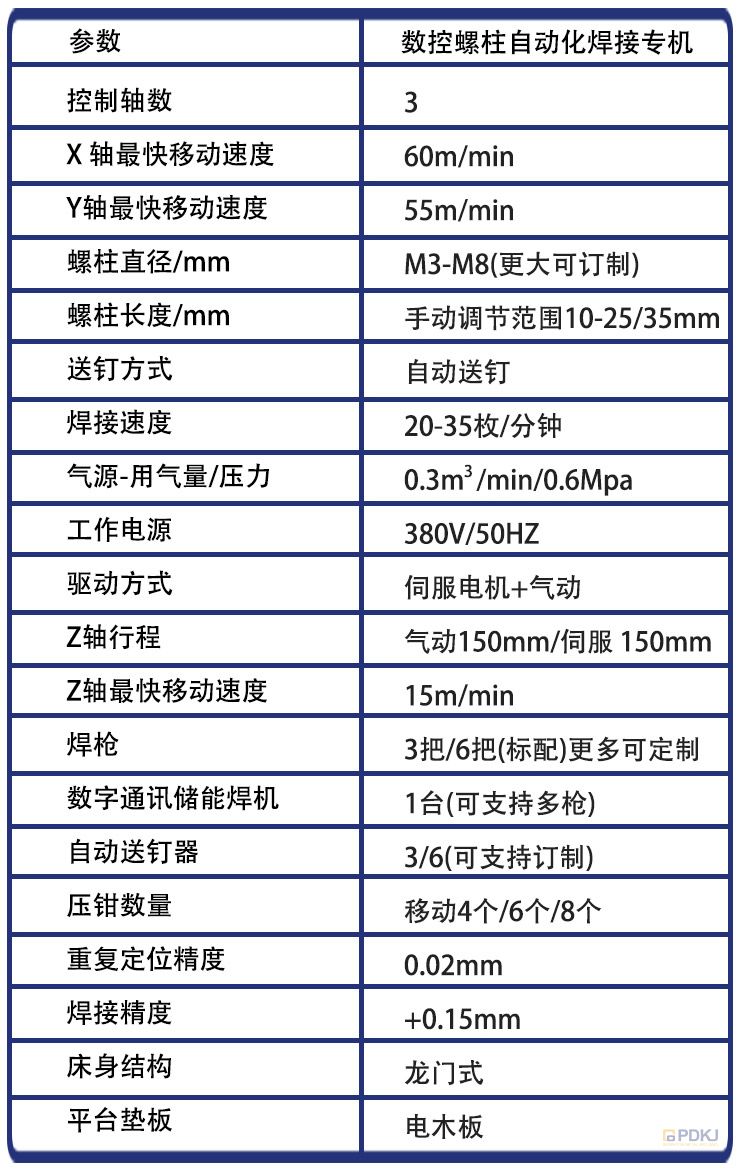

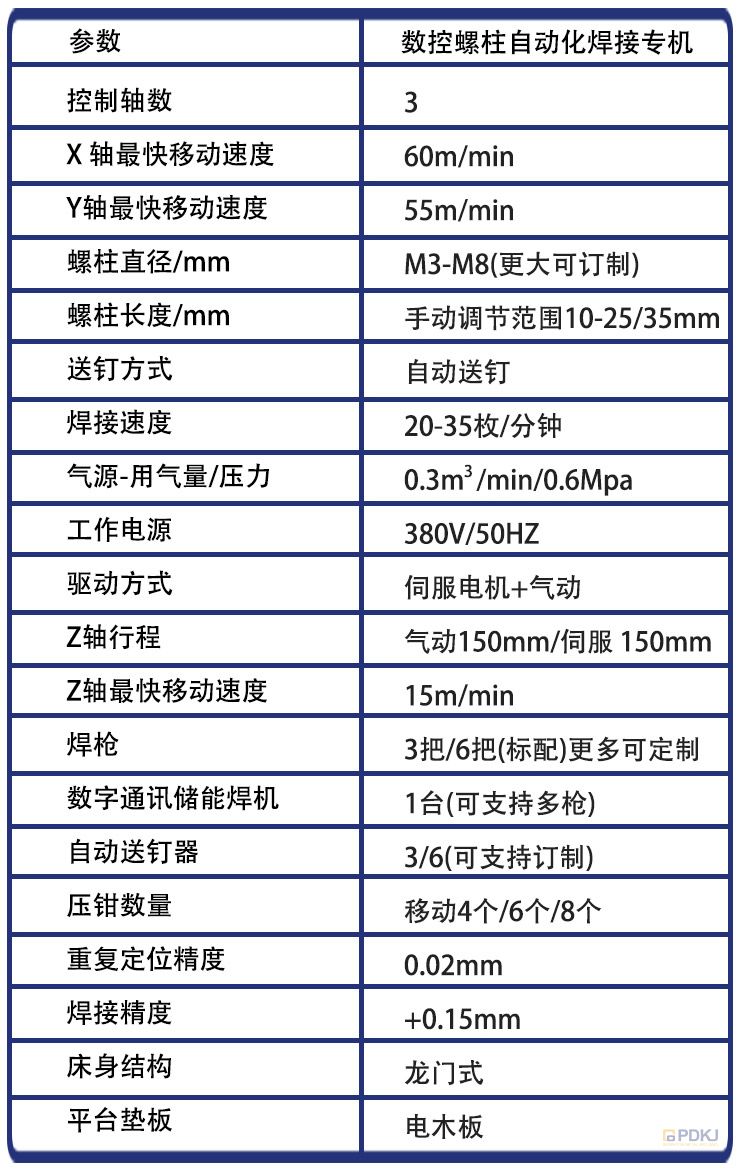

Welding machine parameters

3.Successfully shipped

After careful debugging and rigorous testing, PDKJ's CNC automatic stud welding special machine was successfully delivered to the customer and quickly put into production. The equipment's stable performance, high - efficiency production, and excellent welding quality have won the customer's high praise.

This successful delivery of the CNC automatic stud welding special machine in Hefei's rail transit industry once again powerfully demonstrates PDKJ's strength in welding automation. PDKJ, committed to its mission of "making metal product welding easy worldwide," continues to explore welding technology, innovate product performance, and improve service quality.

In the future, PDKJ will focus on customer needs, driven by technological innovation, and provide more industries with efficient, smart, and reliable welding automation solutions. We'll work with customers to boost Chinese manufacturing toward high - quality and intelligent development, embracing the new era of smart manufacturing.

If you need to weld various non - standard screws, like studs, nut studs, big - head multi - point nails, plain shank studs, or multi - point headless nails, or want to introduce efficient and smart welding equipment to your production line, feel free to contact PDKJ!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713