Product Display

For companies specializing in new energy equipment and accessories, the quality of welding processes directly affects product reputation and market acceptance. A Suzhou-based new energy client, with years of experience in the energy storage and photovoltaic fields, recently introduced PDKJ’s “platform-type medium-frequency inverter spot welding machine” to address welding challenges in metal components, thereby embarking on a new phase of efficient welding.

ⅠProject Background

Over twenty years ago, this Suzhou-based client entered the field of new energy equipment and accessories through metal sheet manufacturing. More than two decades later, it has grown into a diversified comprehensive service provider. In addition to its core metal sheet manufacturing, the company has expanded into other main businesses such as assembly of enclosures and cabinets, racks for semiconductor equipment, plastic welding components, and electromechanical integration assembly.

For many years, the client has continuously expanded its product range to provide supporting services for key scenarios in electronics, energy storage, photovoltaics, semiconductors, rail transit, and other fields, establishing stable cooperative relationships in each area. With the expansion of its business scale and the increasing complexity of its products, the client has set higher standards for welding processes in production and urgently needs reliable welding equipment to ensure production quality.

▶SOURCE

Before introducing PDKJ equipment, the client often faced product rework issues due to the limitations of traditional welding devices. During a technical exchange in the industry, the client learned about PDKJ’s scarless welding technology from a peer. As a professional manufacturer specializing in the research and development of welding machines, PDKJ’s “platform-type medium-frequency inverter scarless spot welding machine” has been put into use in multiple fields such as sheet metal and electrical equipment. Its stable scarless welding effect and efficient working ability have earned it a good reputation in the industry.

Ⅱ Customer welding production pain points

Previously, when the company used traditional resistance welding machines for welding, it always faced three major core pain points:

Inconsistent weld points: Traditional welding equipment struggles to precisely control welding current and time, resulting in uneven weld point sizes that affect product quality.

Surface burn and spatter: During the welding process, spatter and surface burn are easily generated, which not only affect the appearance of the product but may also reduce the strength of the welded joint.

Low welding efficiency: Traditional welding machines have a slow welding speed, which cannot meet the company's growing production demands.

Ⅲ Highlights and advantages of PDKJ welding machine

The PDKJ “DB-170W Platform-type Medium-frequency Inverter Scarless Spot Welding Machine” matches customer needs precisely with its standardized performance and fundamentally solves the pain points:

1. Scarless Welding + Precise Control, Eliminating Secondary Processing

- Equipped with medium-frequency inverter technology and a precision closed-loop control system, the machine can precisely control welding current, time, and pressure. This ensures that the weld point surface is smooth and flat, with no obvious marks on the back, fully meeting the customer's requirements for product appearance. After the machine was put into use, the customer was able to eliminate the grinding process directly, making the production process more streamlined and significantly reducing costs.

2. Flexible Welding Arm + Large Platform, Doubling Efficiency

- The machine has a working surface size of 1000×800mm, and the electrically adjustable platform height ranges from 700 to 800mm. It is also equipped with a multi-angle rotatable welding arm. The horizontal welding torch can easily reach hard-to-weld areas such as the deep cavities and corners of cabinets. The large operating platform not only stably supports the workpieces but can also be adjusted in height according to the workers' needs. Combined with the product's welding parameters, the average daily output of a single machine can be increased by 50%, directly doubling the efficiency.

3. Stable and Durable, Suitable for Multi-material Welding

- In response to the customer's products covering different metal materials such as stainless steel and carbon steel, the machine uses high-temperature-resistant and wear-resistant chromium-zirconium-copper welding components. These components can quickly dissipate welding heat, reducing workpiece deformation and ensuring that all types of metal components maintain stable performance after welding. Moreover, the machine's overall structure is durable, with a low failure rate during long-term use, ensuring continuous production.

4. Humanized Design + Full-cycle Service, Lowering the Usage Threshold

- Considering the operating habits of workshop workers, PDKJ has simplified the machine's LCD touch screen interface. The commonly used welding parameters (such as current and time) are preset in a quick mode. Workers only need to select the corresponding product model to start welding, reducing the learning time to within 1 hour. In addition, after the machine is delivered, PDKJ engineers will stay on-site for the entire installation and commissioning process and provide operational training to ensure that the machine is “ready-to-use” immediately after installation. Subsequently, through regular follow-up visits, they will promptly answer any questions that arise during use to ensure the stable operation of the machine.

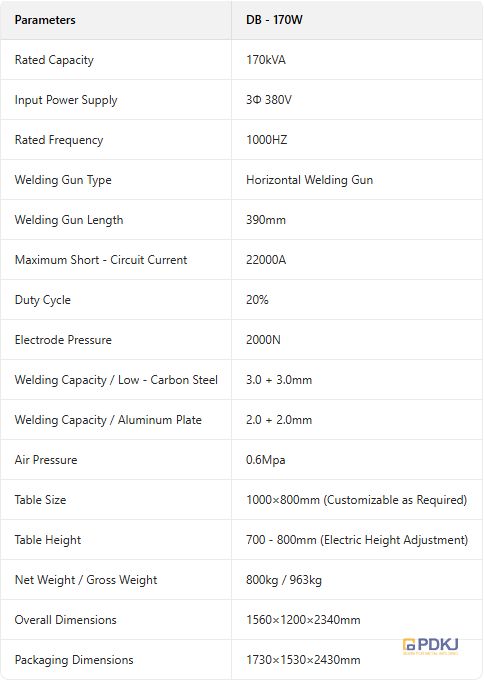

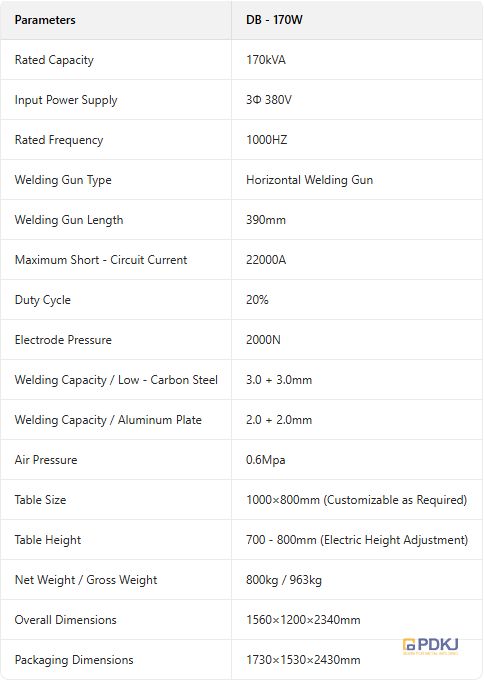

Welding machine parameters

IV. Win - Win Cooperation: Making Metal Welding Effortless

Since the introduction of the PDKJ “Platform-type Medium-frequency Inverter Scarless Spot Welding Machine” to the customer's production line, the welding pass rate of the customer's metal components has significantly increased, with surface defects virtually eliminated and a substantial reduction in rework rates. At the same time, welding efficiency has been notably improved, allowing the customer to easily meet daily order delivery demands without increasing labor.

The customer's production manager commented, “This PDKJ welding machine is easy to operate and has stable performance. It not only solves our long-standing issue with welding appearance but also increases production efficiency. It has become a ‘powerful assistant’ in our production process.”

From new energy metal components to sheet metal enclosures, elevator door panels, and kitchenware hardware, PDKJ has always adhered to the philosophy of “Make Metal Welding Easy for the World,” focusing on the research and development and production of medium-frequency inverter spot welding machines and scarless spot welding machines. We can provide customized welding solutions based on the needs of different industries and workpieces.

Purchase Invitation

If you are troubled by welding issues for metal switch boxes, electrical control cabinets, communication cabinets, control cabinets, and other products in the new energy field, please contact us at Guangdong PDKJ Automation Technology Co., Ltd. Our professional technical team, high-quality welding equipment, and comprehensive service system will provide you with the most suitable welding solutions. Let PDKJ become your powerful partner in welding, jointly tackle welding challenges, enhance product quality and production efficiency, and promote the vigorous development of your enterprise. PDKJ, your welding expert, looks forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713