Product Display

In today's era of intelligence and automation, the demand for smart lockers and cabinets is growing rapidly. Whether it's smart lockers in commercial settings or intelligent cabinets in the industrial field, their production process relies on high - quality welding technology. PDKJ, with its advanced welding technology and equipment, has provided an excellent welding solution for smart cabinets to customers in Hubei's smart Internet of Things industry, helping them improve production efficiency and product quality.

I. Project Background

The customer in Hubei is a company that specializes in the production of smart lockers and cabinets. Their products are widely used in commercial, industrial, and public service sectors, providing users with secure and convenient storage solutions.

With the continuous growth of market demand, traditional welding methods are not only inefficient but also fail to ensure welding quality. The strength and appearance of the weld seams directly affect the overall performance and service life of the cabinets. Moreover, as the production scale expands, the customer urgently needs an efficient and stable welding device to improve production efficiency while ensuring welding quality to meet production demands.

*SOURCE

Recommended by partners in the same industry, the company learned about PDKJ's mature experience in the field of smart equipment welding and proactively reached out to seek customized solutions.

II. Customer's Pain Points and Requirements in Production Welding

The smart cabinets produced by the company mainly use thin carbon steel plates for the main body. Dense spot projection welding is required for areas such as the door panels and frames, as well as the internal partitions and uprights. The previous production mode relying on traditional power - frequency welders has exposed many problems:

Low Welding Efficiency: Traditional welding equipment cannot meet the needs of large - scale production, resulting in long production cycles and untimely order delivery.

Unstable Welding Quality: Traditional welding methods are prone to welding defects, such as uneven weld seams, virtual welding, and weld - through, which affect the overall quality and service life of the product.

Material Diversity: The production of smart lockers and cabinets involves a variety of materials, such as aluminum alloy and stainless steel. Each material has different welding processes and parameters. A welding device that can adapt to multiple materials is needed.

III. PDKJ Welder Highlights and Advantages

Against this backdrop, PDKJ's Intermediate Frequency Inverter DC Spot Welder, with its outstanding performance and innovative technology, has perfectly solved the customer's welding pain points and become the ideal choice for the production of smart lockers and cabinets.

1. Accurate Welding to Improve Quality

The welder converts power - frequency AC to medium - frequency DC output, significantly enhancing time resolution and control accuracy. This means a more precise welding process that can effectively avoid welding defects and improve welding quality.

2. Fast Welding Speed and High Production Efficiency

With high thermal efficiency and a large output power ratio, the welding speed is fast, greatly improving production efficiency. Compared with traditional power - frequency welders, the inverter - type medium - frequency DC welder also has the characteristics of high efficiency and energy saving, which can save a lot of energy costs for users.

3. Wide Range of Applications

In practical applications, PDKJ's Intermediate Frequency Inverter DC Spot Welder has shown excellent performance. It is particularly suitable for welding metal materials such as aluminum, copper, galvanized steel, carbon steel, nickel, and tungsten, which are commonly used in the production of smart cabinets. Whether it is the welding of products such as lockers, parcel boxes, sorting cabinets, meal - picking cabinets, or charging cabinets, PDKJ's welder can easily cope with it, ensuring the firmness and beauty of the welding parts.

4. Intelligent and Automated

The welder is equipped with an advanced intelligent control system that can automatically adjust welding parameters to ensure the stability and consistency of the welding process. PDKJ also provides automated welding solutions, such as intelligent robot - based flexible welding workstations, which can achieve full - automation operations from sheet metal handling, positioning to welding, further improving production efficiency and product quality.

Since its launch, this customer in Hubei has clearly felt the improvement in production efficiency and welding quality. The weld seam is more uniform and smooth, and the overall quality of the cabinet has been significantly improved.

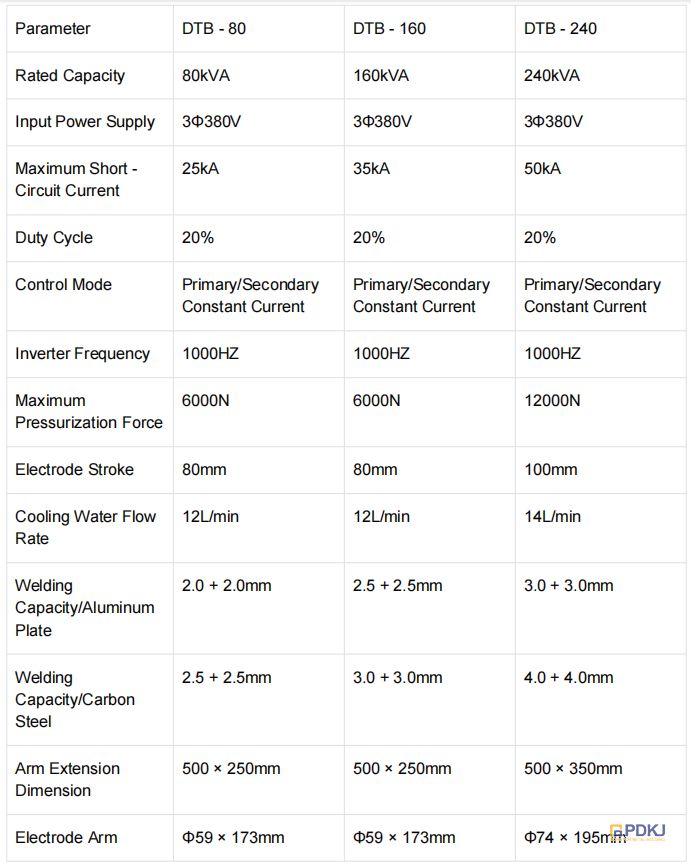

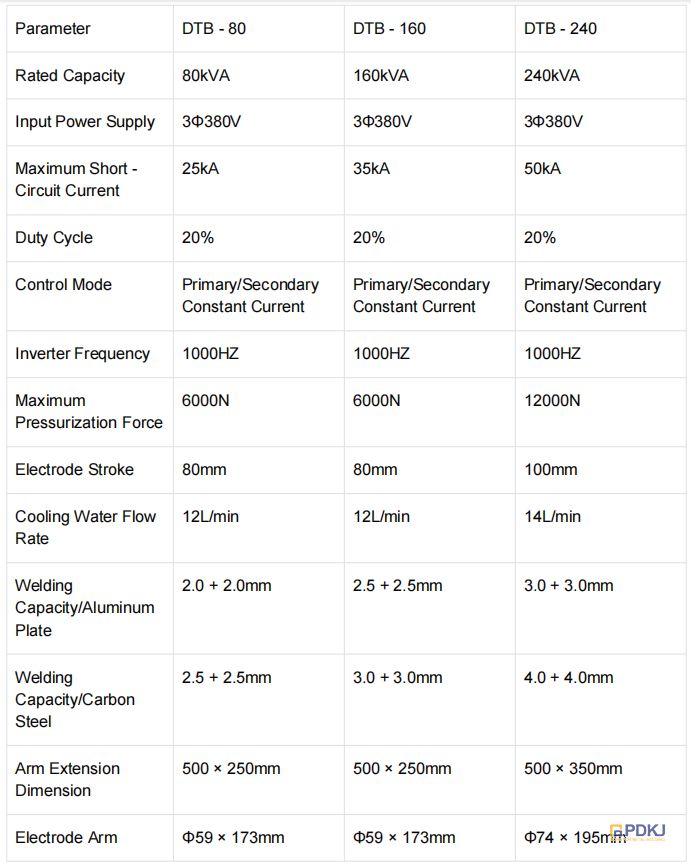

Welding machine parameters

IV. Win - Win Cooperation: Making Metal Welding Effortless

Customer Feedback: "PDKJ's Intermediate Frequency Inverter DC Spot Welder DTB - 240 has completely solved our production problems. After the equipment was put into use, not only did the production capacity keep up with the order rhythm, but the cabinet welding quality also improved significantly. Now these welders have become the core equipment of our production line, and we will prioritize PDKJ's products for future expansion."

PDKJ is always committed to providing customers with high - quality welding equipment and services. Our Intermediate Frequency Inverter DC Spot Welder has not only been successfully applied in the smart Internet of Things industry in Hubei but also demonstrated strong capabilities in many other fields, such as automotive and automotive parts manufacturing, new energy power batteries, optoelectronic communications, electric light sources, hardware, furniture, and cookware. Whether you are producing smart cabinets or other metal products that require welding, PDKJ can provide you with suitable welding solutions.

Purchase Invitation

If you are troubled by the metal welding problems of smart lockers, courier lockers, refrigerated lockers, storage lockers, tool lockers, and other smart cabinets in the smart Internet of Things industry, feel free to contact Guangdong PDKJ Automation Technology Co., Ltd. - - with a professional technical team, high - quality welding equipment, and a comprehensive service system, we will provide you with the most suitable welding solutions. Let PDKJ become your reliable partner in welding, jointly tackle welding challenges, enhance product quality and production efficiency, and boost the development of your enterprise. PDKJ, your welding expert, looks forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713