Laser welding is a cutting-edge technology widely used in modern industries for joining metal components with extreme precision. As industries shift towards automation and high-precision manufacturing, laser welding machines have become indispensable tools, offering high speed, low thermal distortion, and superior quality.

At its core, laser welding is a technique that uses a concentrated beam of light to melt and fuse materials. Unlike traditional welding methods, which often involve contact and high mechanical force, laser welding is a non-contact, highly controlled process. This results in cleaner, more accurate, and faster welds, making it ideal for applications in automotive, aerospace, electronics, medical devices, and more.

Working Principle of a Laser Welding Machine

A Laser Welding Machine operates on the principle of using concentrated, high-energy laser beams to melt and fuse materials at their joint. This process is fast, precise, and generates minimal heat-affected zones, making it ideal for applications requiring clean and accurate welds. To understand how this technology works, let’s break down the core stages involved in the process—starting from laser generation to the final formation of the weld.

Laser Generation and Transmission

At the heart of every Laser Welding Machine is its laser source. The role of the laser source is to generate a beam of coherent light that is highly focused and directed to the target workpiece. Several types of laser sources are used depending on the application, material type, and required output power.

1. Fiber Lasers

Fiber lasers are the most widely used in modern laser welding machines, particularly in high-precision and high-speed industrial applications. These lasers generate the beam through optical fibers doped with rare-earth elements such as ytterbium. The laser beam is then transmitted through the fiber with minimal energy loss, resulting in:

High beam quality

Excellent focusability

Energy efficiency

Low maintenance

Because of their reliability and scalability, fiber lasers are ideal for robotic and automated welding systems.

2. CO₂ Lasers

CO₂ lasers generate infrared laser light using a mixture of gases (typically carbon dioxide, nitrogen, and helium). These lasers are effective in cutting and welding non-metallic materials like plastics, wood, and ceramics. However, in the context of laser welding, they are also used for thicker metallic materials when beam delivery via mirrors is feasible.

While CO₂ lasers offer high power levels, they have limitations in precision applications due to:

3. Nd:YAG Lasers

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers were traditionally popular for laser welding machines due to their ability to operate in both continuous and pulsed modes. They also offered flexibility in beam delivery through fiber optics. However, with the rise of fiber lasers offering better electrical efficiency and lower operational costs, Nd:YAG lasers have largely been phased out in favor of more advanced technologies.

Beam Transmission and Focusing

After generation, the laser beam needs to be transported to the weld site. This is typically done through:

The beam is then focused using precision lenses onto a small area of the workpiece. This concentrated energy creates intense localized heating, enough to melt the base materials without affecting surrounding zones.

Focusing, Heating, and Melting the Material

The focused beam produced by a laser welding machine delivers immense energy into a pinpoint location, causing the material to heat rapidly and form a molten pool. This molten pool travels along the joint as the laser moves or is guided along the weld path.

Several factors determine how deeply and effectively the weld penetrates:

Laser Power: Higher power results in deeper penetration and faster welding speeds.

Focal Spot Size: A smaller spot size increases energy density, enabling better melting.

Welding Speed: Faster speeds reduce heat input, affecting penetration and bead shape.

Material Type and Reflectivity: Metals like aluminum and copper reflect laser light and may require higher energy or specialized wavelengths.

As the laser beam progresses, the molten pool quickly cools and solidifies, forming a high-strength weld seam. The fast heating and cooling rates minimize distortion and preserve the material’s structural integrity.

Welding Process Steps in a Laser Welding Machine

The functionality of a laser welding machine can be better appreciated when examined as a step-by-step process. Each stage—from material preparation to solidification—is crucial for achieving consistent, high-quality welds.

1. Material Positioning

Accurate material positioning is critical in laser welding. Before the welding process begins, the workpieces must be precisely aligned to ensure that the laser beam is focused exactly on the joint. Depending on the setup, this can be done using:

High-precision fixtures

CNC-controlled tables

Robotic arms

Vision-guided systems

In automated environments, machine vision cameras detect and correct deviations in real-time, ensuring proper alignment even for complex or variable geometries.

2. Laser Beam Irradiation and Control

Once materials are properly positioned, the laser welding machine activates the laser. The machine’s control system directs the beam to the joint using mirrors or fiber optics. This stage involves real-time control over critical parameters, such as:

Laser Power Output: Dictates the amount of energy being delivered.

Pulse Frequency (in pulsed mode): Number of energy bursts per second.

Travel Speed: Speed at which the laser moves across the joint.

Focal Length Adjustment: Keeps the beam in focus on the weld surface.

Advanced laser welding machines feature closed-loop feedback systems that adjust these variables on-the-fly to ensure stable welding, even if the material or environment changes.

3. Melting, Cooling, and Weld Formation

As the laser beam contacts the joint, it generates enough heat to melt the metal, forming a molten weld pool. The depth and width of the weld are controlled by the laser’s parameters and material properties.

As the laser advances:

The trailing edge of the molten pool cools and solidifies.

A solid weld seam forms that fuses the two materials permanently.

This process can occur in continuous mode or pulsed intervals, depending on the welding technique and application.

Cooling rates in laser welding are typically very fast, which contributes to:

Types of Laser Welding Techniques

Laser welding machines can operate in several modes, each suited for different applications.

1. Continuous Wave (CW) Welding

In this mode, the laser emits a constant beam of light, making it ideal for long, uninterrupted welds. It’s often used in high-speed production lines, especially in automotive manufacturing. CW welding usually requires high power, from 1000W to 6000W.

2. Pulsed Laser Welding

This method emits laser energy in short, high-intensity pulses. It’s best for welding thin materials or small components that are sensitive to heat. Pulsed welding is commonly used in:

Electronics

Jewelry

Medical devices

Power levels here are much lower, typically between 50W and 500W.

3. Keyhole Welding vs. Conduction Welding

Keyhole Welding (Deep Penetration): The laser’s high power vaporizes the material, creating a narrow, deep hole known as a "keyhole." This allows the weld to penetrate deep into the material. It’s ideal for thick materials and structural applications.

Conduction Welding (Surface Fusion): The laser heats only the surface, causing shallow melting. It’s suitable for thin metals and precision applications where minimal heat distortion is critical.

Precision and Control

What sets laser welding apart is not just its speed or heat—it’s the precision and control it offers.

Laser Power, Pulse Frequency, and Focal Adjustment

Laser Power: Determines how much energy is delivered to the workpiece. More power allows for deeper welds or faster operation, but too much can burn or distort the material.

Pulse Frequency: In pulsed welding, this defines how many bursts of energy are delivered per second. Higher frequencies result in smoother, more consistent welds.

Focus Adjustment: The focal point must be aligned exactly on the welding surface. A misaligned focus can lead to poor fusion or weak joints.

Automatic Control and Vision Systems

Modern laser welding machines are equipped with real-time monitoring, automatic feedback loops, and machine vision systems. These technologies ensure:

In advanced setups, AI and machine learning are even being used to optimize welding parameters automatically, further improving quality and efficiency.

Conclusion

Laser welding is a marvel of modern engineering—combining high energy, precise control, and smart automation. From generating the laser beam to forming clean, durable welds, the process is built for speed, accuracy, and strength. Whether used in electronics, automotive, or high-end manufacturing, its versatility and precision make it an essential solution.

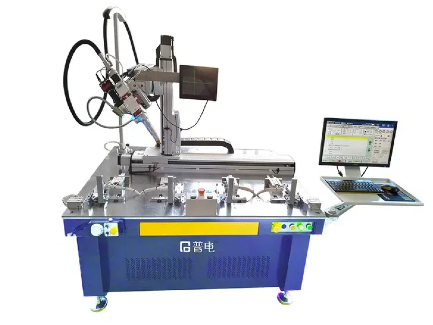

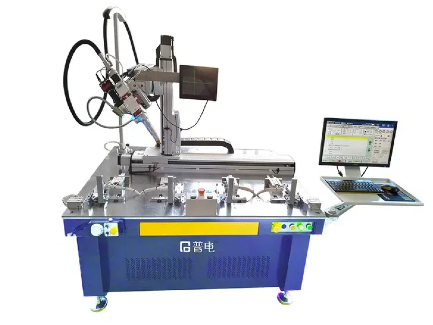

If you're looking to explore laser welding technology or invest in a reliable laser welding machine, we recommend connecting with Guangdong Pudian Automation Technology Co., Ltd. As a trusted manufacturer specializing in advanced welding solutions, Pudian offers expert guidance and high-performance equipment tailored to your needs. Visit their website or contact their team today to learn more.