"Choosing the right welding equipment can save a lot of production trouble"—this is a common understanding among many manufacturing companies.

In this article, we will introduce a real-world case study: PDKJ, leveraging its mature technological capabilities, successfully delivered handheld laser welding machines to a customer in the Foshan rail transit industry, helping the customer achieve efficient and high-quality welding of aluminum subway gates and successfully fulfilling the project's production requirements.

I. Project Background

The Foshan-based client in this collaboration has a long history of specializing in rail transit equipment. Their core product, barrier gates, are widely used in the supporting infrastructure of major city subways and high-speed rail stations.

Previously, the client primarily relied on manual arc welding and TIG welding machines for barrier gate welding. However, these two traditional methods have gradually shown limitations in actual production, directly restricting production efficiency and quality consistency:

Manual arc welding machines: The weld seams have poor flatness and are prone to undercut and slag inclusion problems, requiring additional labor for rework and grinding, thus slowing down the production pace;

TIG welding machines: They have a high operating threshold, heavily relying on the technical proficiency of the workers, and the welding speed is slow. When dealing with the multi-curved and multi-joint structures of the barrier gates, they are difficult to adapt flexibly, leading to significant fluctuations in weld quality across different batches of products.

These issues not only affect the production cycle of individual barrier gates but also increase the risk of quality control rework.

II. Customer's Welding Requirements

To ensure the stable operation of barrier gates in transportation hubs, the customer has specific requirements for product welding:

The welding quality must strictly meet the structural strength and surface flatness standards of the rail transit industry, ensuring the long-term reliability of the barrier gates;

The welding equipment must be adaptable to the multi-part, multi-connection structures of the barrier gates, improving production efficiency to guarantee project delivery timelines;

The welding equipment should require no complex debugging and be easily integrated into existing production lines. It must improve welding efficiency to maintain the pace of mass production while ensuring consistent and uniform weld quality.

At the same time, it should be flexible enough to adapt to the welding requirements of other products within the company, such as vehicle frames, brackets, chassis casings, and traffic decorative accessories, increasing equipment utilization and reducing operational difficulty.

III. Highlights and Advantages of PDKJ Welding Machines

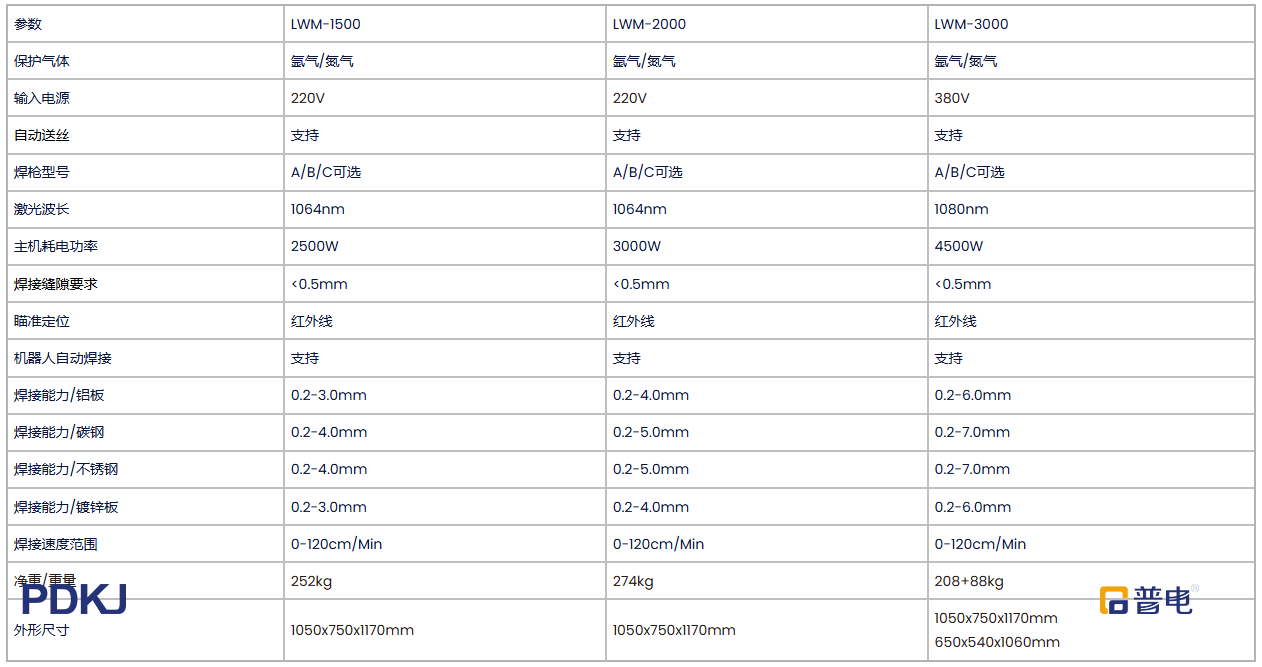

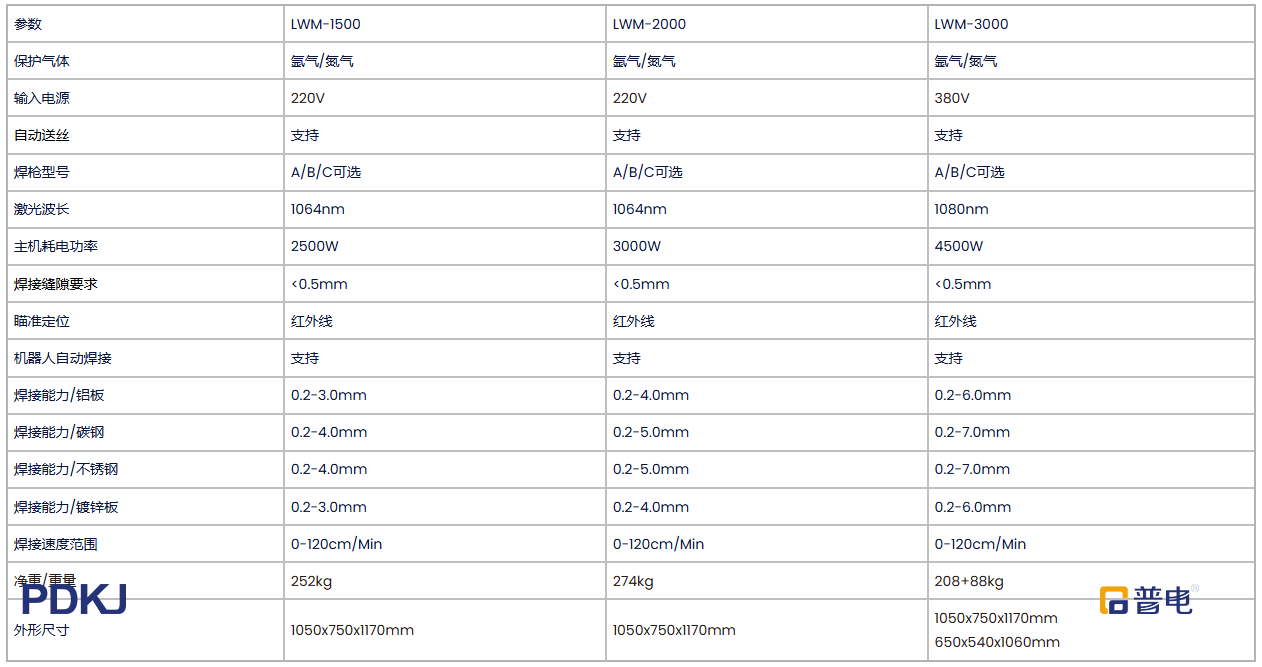

Based on the customer's welding requirements, PDKJ, considering the structural characteristics and welding process requirements of aluminum subway gates, and after communication and prototyping, finally determined that a 2000W handheld laser welding machine would be the core solution. Leveraging the performance advantages of the equipment, it easily meets production requirements:

1. High Efficiency and Stability, Ensuring Production Pace

The equipment uses a high-energy-density laser beam to achieve low heat input welding, significantly reducing the heat-affected zone during aluminum welding, effectively avoiding common defects such as deformation, porosity, and cracks in traditional processes. This ensures a smooth appearance and undamaged structural strength after welding the gate. The welding speed is superior to traditional equipment, allowing for rapid completion of welding operations on various connection points of the gate, effectively shortening the production time per gate and helping the customer advance project delivery on schedule.

2. Precise Welding Control, Flexible Adaptation to Multiple Specifications

Equipped with a high-precision wire feeding system and stable power output, it ensures a stable molten pool and uniform and aesthetically pleasing welds during the welding process. Preset welding parameters for different thicknesses of aluminum gates allow for one-click recall during production, simplifying the operation process.

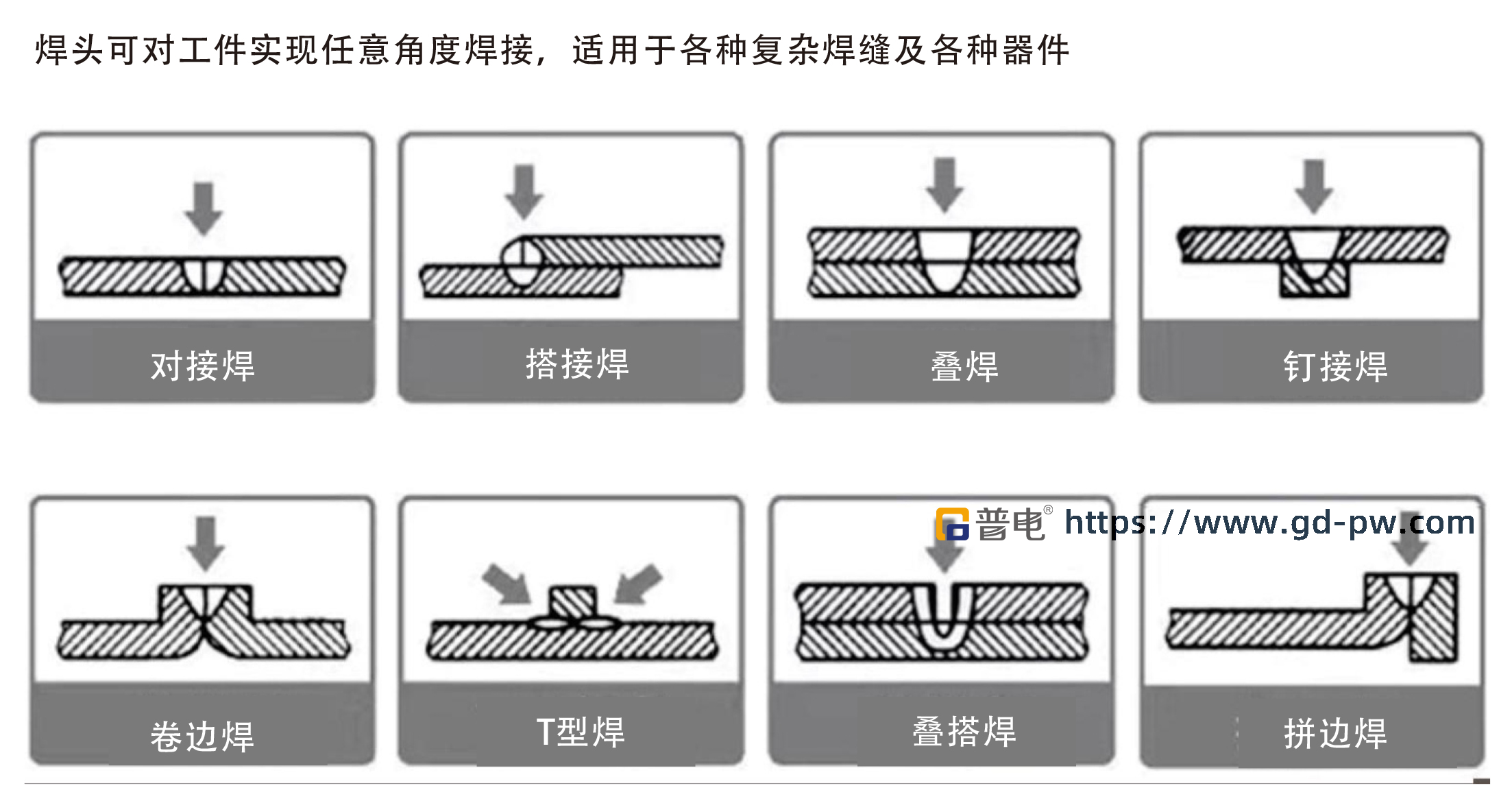

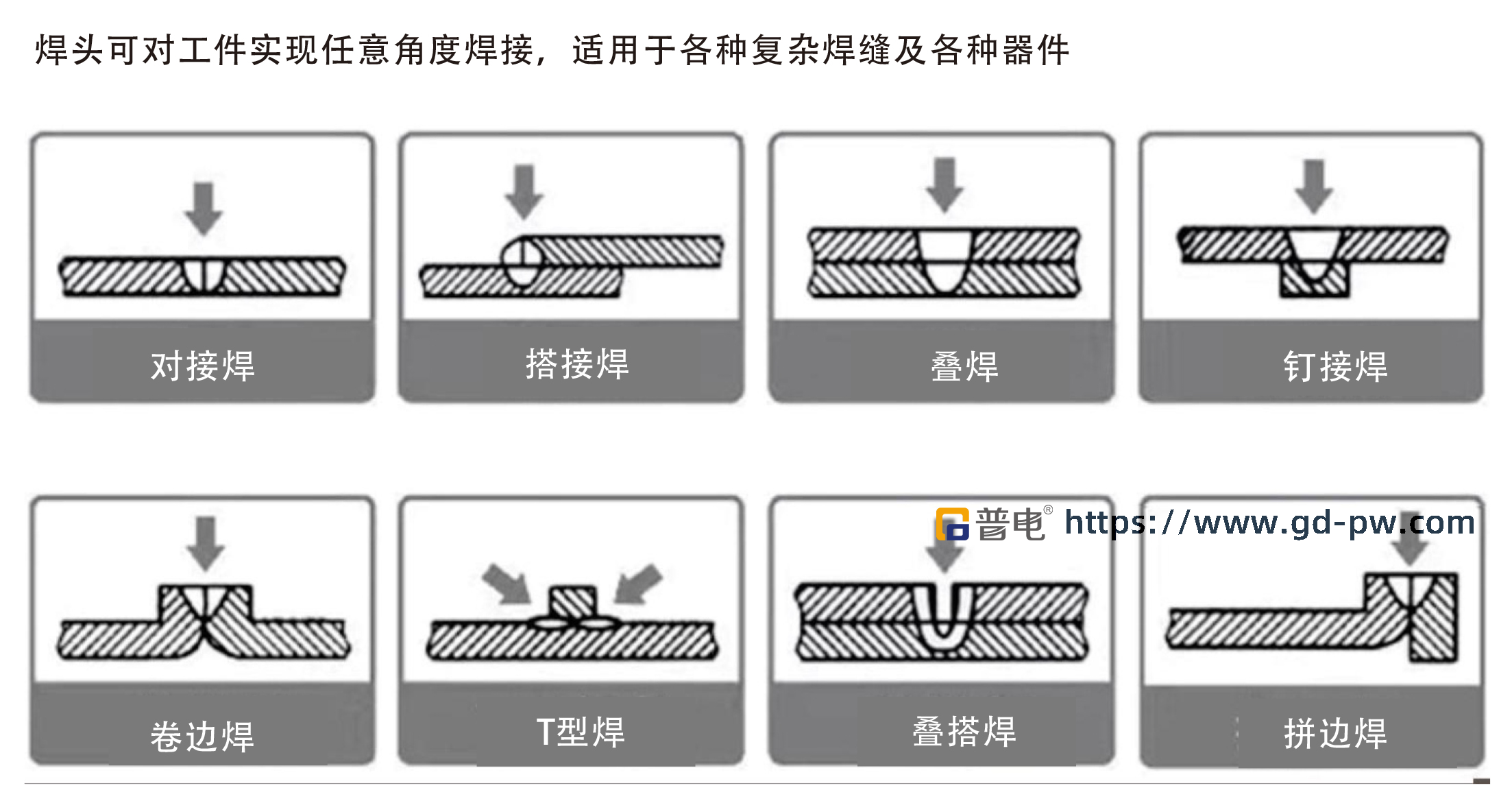

3. Flexible Operation, Adapting to Gate Structure

The handheld design with an adjustable welding head can flexibly handle the narrow welding spaces and multi-curved connection points of the gate, eliminating the need for frequent adjustments of fixtures and allowing for efficient operation by a single person, greatly simplifying the production process and reducing operational complexity.

4. Convenient and Easy to Use, Ensuring Welding Consistency

The built-in "user-friendly" operation interface (supporting Chinese and English switching) allows new employees to operate independently after only 2 hours of training, solving the talent problem of traditional welding's "reliance on experienced welders"; the equipment comes with a welding parameter memory function, achieving 99% welding consistency for different batches and specifications of gates, completely eliminating the problem of "quality fluctuations."

5. Multi-functional Integrated Application

The 2000W handheld automatic wire feeding fiber laser welding machine integrates welding, cutting, and cleaning functions, and can weld various materials such as carbon steel, stainless steel, galvanized sheet, and aluminum alloy, greatly reducing equipment investment costs and increasing flexibility of use.

Welding Machine Parameters

IV. Win-Win Cooperation: Make Metal Welding Easy for the World

Currently, PDKJ handheld laser welding machines have been operating stably in the customer's production workshop for several months. Thanks to these welding machines, the customer recently delivered a subway station gate project in a provincial capital city. The project passed the client's rigorous acceptance testing on the first try, thanks to the uniform and smooth welds, and the satisfactory tensile strength and corrosion resistance.

All of the gates in this batch have now been installed and are operating stably during daily use. The equipment's actual performance perfectly matches the customer's expectations for "rail transit-grade welding quality."

This successful delivery of the Foshan rail transit aluminum subway gate project is another practical achievement for PDKJ handheld laser welding machines in the transportation infrastructure sector.

As a company focused on the research, development, and production of welding machines, PDKJ is committed to the mission of "Make Metal Welding Easy for the World," while also addressing the individualized needs of different customers – whether it's standardized equipment directly adapted to conventional production or customized solutions for special scenarios, PDKJ can respond to industry needs with professional technology. In the future, PDKJ will continue to deepen its innovation in welding technology, providing higher-quality products and services to customers in the rail transit, new energy, building materials, and other fields, empowering high-quality industrial development with efficient welding technology.

Purchase Invitation

If you are struggling with welding issues for products such as carriage components, door frames, subway gates, platform screen doors, seat brackets, electrical equipment housings, metal enclosures, metal junction boxes, and vehicle decorative parts, please contact Guangdong PDKJ Automation Technology Co., Ltd. immediately. Our professional technical team, high-quality welding equipment, and comprehensive service system will provide you with the most suitable welding solutions. Let PDKJ be your reliable partner in welding, helping you overcome welding challenges, improve product quality and production efficiency, and contribute to the thriving development of your business. PDKJ, your trusted welding expert, looks forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713