Sample Display

“Uneven weld points on connectors and high defect rates, and when changing specifications, it takes half a day to adjust the equipment and still can't meet the requirements” —— This is perhaps a common dilemma for many electronic and electrical enterprises in the precision component welding process. Especially when the welding quality of the core components directly affects the performance of the entire machine, choosing a reliable welding device can often lead to a dual breakthrough in production efficiency and product reputation.

Today, we would like to share a real - life case of how PDKJ used a Desktop AC Precision Spot Welder DN - 25T to solve the welding problem of automotive connectors for an electronic and electrical enterprise in Dongguan.

I. Project Background

The customer in this collaboration is a local Dongguan - based company that has been deeply involved in the electronic and electrical field for many years. Its products cover several niche areas, including consumer electronics and industrial control. The company has accumulated a number of long - term customers in the market thanks to its stable quality. As the downstream customers' requirements for product precision continue to increase, the company has gradually felt the limitations of traditional equipment in the core production process - connector welding. Although connectors are small, they are the "bridge" for the normal operation of electronic devices. Once there is a problem with the welding, it can lead to product repairs at best and affect customer trust at worst. Therefore, finding a suitable precision welding device has become the key for the company to improve production efficiency.

II. Customer's Pain Points and Requirements in Production Welding

Before introducing the PDKJ DN - 25T spot welder, the connector welding process of this company was troubled by three major pain points:

1. Insufficient welding precision

Traditional equipment cannot precisely control current and pressure. When dealing with small - sized connectors, it often leads to offset weld points and virtual welding. As a result, some products fail quality inspection due to welding issues.

2. Poor equipment flexibility

The company produces connectors in a variety of specifications, and the materials include copper alloys, aluminum alloys, and so on. Each time the specification is changed, traditional equipment needs to repeatedly adjust parameters. The debugging process takes a long time, which seriously slows down the production rhythm.

3. Subpar stability

During operation, the equipment occasionally experiences current fluctuations. This not only increases the risk of welding defects but also requires frequent shutdowns for inspection, disrupting the normal production rhythm of the assembly line.

Based on these pain points, the customer clearly put forward the demand: they need a spot welder that can achieve high - precision welding, is compatible with multiple - specification products, and has stable operation. It should not only solve the current production problems but also meet the welding requirements of future product upgrades.

III. PDKJ Welder Highlights and Advantages

In response to the customer's core requirements, the PDKJ team, after multiple communications and process analyses, ultimately recommended the Desktop AC Precision Spot Welder DN - 25T. The reason this equipment can precisely match the customer's needs lies in its three major core advantages:

1. Precision Control to Ensure Welding Quality

The equipment is equipped with an advanced microcomputer controller that can precisely regulate welding current and pressure. The minimum current adjustment accuracy can reach 1A, and the pressure control error does not exceed 5N. For the connectors produced by the customer, the equipment can ensure that the weld points are centered and free of virtual connections through precise parameter settings, while also avoiding product burnout caused by excessive current. In actual use, the customer's connector welding defect rate has decreased by nearly 98% compared to before, and the product rework cost has been significantly reduced.

2. Flexible and Compatible Design to Meet Multi - Specification Production Needs

Considering the customer's need to switch production between different - specification connectors, the DN - 25T has been optimized in structural design: The equipment is equipped with quickly changeable electrodes and fixtures. The replacement process is simple and convenient, and can be quickly completed without professional technical personnel. At the same time, the water - saving circulating water - cooling system is equipped with quick - connect water - cooling fittings, which can flexibly adjust the cooling efficiency according to the welding heat - dissipation requirements of different - material connectors. Whether it is copper - alloy or aluminum - alloy connectors, stable welding can be achieved, greatly reducing the customer's production - change debugging time.

3. Stable and Reliable Performance to Ensure Continuous Assembly - Line Operation

The equipment adopts a high - strength machine body structure with good rigidity, which is not easy to deform during operation and ensures the stability of welding parameters. The pneumatic system uses high - performance components with stable pressure output, reducing downtime caused by equipment failures. Since the equipment was put into use, the customer's welding workstation has achieved continuous stable operation for 8 hours without downtime caused by equipment failures, effectively ensuring the production rhythm of the assembly line.

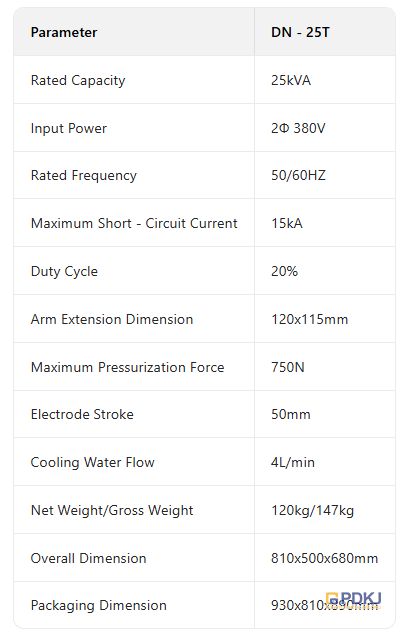

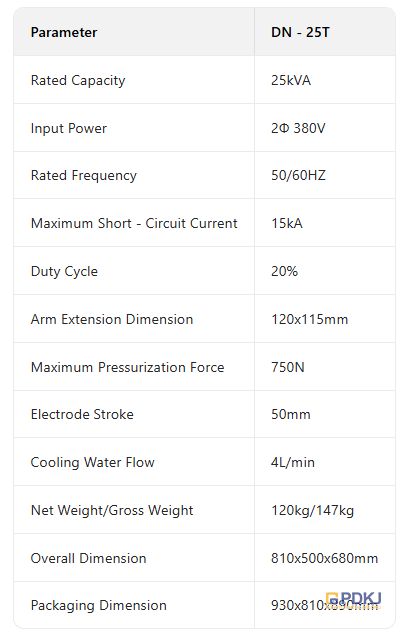

Welding machine parameters

IV. Win - Win Cooperation: Make Metal Welding Easy for the World

From the initial demand communication and process testing to the later stages of equipment installation, commissioning, and operator training, the PDKJ team has followed through the entire process to ensure the rapid implementation and production of the equipment. Now, the DN - 25T has become the "main equipment" in the customer's automotive connector production process. It has not only solved the previous welding pain points but also provided technical support for the company's future development of higher - precision connector products, truly achieving "one cooperation, long - term benefits."

In fact, the welding challenges faced by this Dongguan - based electronic and electrical enterprise are not unique. In the field of precision manufacturing, whether it is electronic components, automotive parts, or medical device accessories, there may be difficulties in welding. Over the years, PDKJ has always focused on the research and development and customization of welding equipment. In addition to desktop precision spot welders like the DN - 25T, it also has multiple product lines, including medium - frequency spot welders, energy - storage spot welders, platform - type mark - free spot welders, and automated welding special machines. It can provide customized solutions according to the welding requirements of different industries and workpieces.

Purchase Invitation

If you are troubled by welding problems of connectors, terminals, sensors in the electronics industry, small metal parts in the automotive industry, or precision metal components of medical devices, feel free to contact Guangdong PDKJ Automation Technology Co., Ltd. - - with a professional technical team, high - quality welding equipment, and a comprehensive service system, we will provide you with the most suitable welding solutions. Let PDKJ become your reliable partner in welding, jointly tackle welding challenges, enhance product quality and production efficiency, and boost the development of your enterprise.

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713