Product Display

Hot formed steel nut

In the field of new energy vehicle manufacturing, the welding quality of key body parts directly determines the safety and durability of the whole vehicle. Among them, hot-formed steel nuts, as the “link” connecting the vehicle body frame and core components, have become a typical challenge in the welding process due to their high material hardness and strong thermal conductivity.

Recently, PDKJ’s Capacitive Energy Storage Spot (Projection) Welding Machine was successfully delivered to a leading new energy vehicle manufacturer in Hefei, providing a customized solution for its hot-formed steel nut welding production line, fundamentally solving the quality fluctuations and efficiency bottlenecks of traditional welding.

Ⅰ Project Background

The Hefei customer involved in this cooperation is one of the core manufacturers in China's new energy vehicle industry, focusing on the research and development and production of new energy passenger vehicles, power batteries, and vehicle control systems, with products covering the domestic and global markets. In its body manufacturing process, the welding process of hot-formed steel nuts is particularly critical —— these nuts need to be firmly connected to the vehicle body frame, not only withstanding long-term vibrations during vehicle operation but also ensuring the precision of subsequent assembly. Therefore, three core requirements are put forward for welding:

Material compatibility, which can stably weld high-strength hot-formed steel and avoid problems such as false welding and incomplete weld nuclei;

Weld point reliability, the strength of the weld point needs to meet the safety standards of the automotive industry, and the strength of each weld point must be uniform;

Production compatibility, which is compatible with the mass production rhythm of the whole vehicle, and the welding efficiency and stability need to meet the continuous operation requirements of the assembly line.

Ⅱ Customer welding production pain points

Before the introduction of PDKJ's equipment, the customer's hot-formed steel nut welding process had long been plagued by three major problems, which directly affected production progress and product yield:

Unstable weld point quality: The large output current fluctuations of traditional welding machines, combined with the high thermal conductivity of hot-formed steel, often resulted in insufficient local heat, causing issues such as small weld nuclei and insecure connections between nuts and steel plates. Some parts had to be reworked, increasing production costs.

Poor weld point appearance: The slow heat dissipation during the welding process led to oxidation and blackening around the weld points. Subsequent manual grinding was required, which not only added extra steps and labor costs but also potentially affected the dimensional accuracy of the nuts due to over-grinding.

High dependence on the power grid: Traditional welding machines have high instantaneous power demands. During peak electricity usage in the workshop, they are susceptible to power grid fluctuations, causing welding parameter drift. This further exacerbates quality fluctuations and may even lead to temporary production line shutdowns.

During the initial communication, the PDKJ team visited the customer's production workshop multiple times to observe the welding scene and analyze the characteristics of the workpiece. Eventually, they decided to use a 15000J capacitor energy storage point (convex) welding machine as the core, combined with exclusive welding parameters and fixtures, to create an adaptive solution.

Ⅲ Highlights and advantages of PDKJ welding machine

In response to the customer's needs, PDKJ's 15000J Capacitive Energy Storage Spot (Projection) Welding Machine, with its unique technological advantages, has achieved precise solutions:

1. Accurate Matching for Hot-Formed Steel:

- The machine employs "capacitive energy storage - instantaneous discharge" technology. During welding, the energy is concentrated and released rapidly, forming a stable weld nucleus at the contact point between the hot-formed steel and the nut. This prevents the issue of incomplete weld nuclei caused by heat dissipation. Additionally, the machine can precisely adjust the discharge energy based on the thickness of the hot-formed steel and the specifications of the nut, ensuring consistent welding quality across different workpiece sizes.

2. Stable Energy for Consistent Quality:

- The welder has a strict "charging threshold control." It only initiates the discharge welding process when the capacitor is charged to the set voltage, completely eliminating the influence of power grid fluctuations. In actual use, the deviation in welding energy is less than 3% each time. The strength of all nut weld points is uniform, and the customer's inspection pass rate has increased to 99.8%.

3. Quick Switching and Adjustment:

- The machine is equipped with a simple touch-screen operation interface that can store multiple sets of welding parameters for hot-formed steel nuts. When the customer switches to different nut specifications, there is no need for repeated adjustments. Simply retrieve the preset parameters with one click to start welding, significantly reducing changeover time and further enhancing mass production efficiency.

4. Aesthetic Weld Points with No Post-Weld Processing:

- The discharge time of the capacitive energy storage spot/projection welding machine is extremely short, with heat concentrated only in the weld nucleus area. The welding is completed before the heat can dissipate, resulting in weld points that show no significant discoloration or oxidation marks. This fully meets the customer's requirement for "direct assembly without grinding," eliminating the need for subsequent manual grinding processes. This not only reduces labor costs but also avoids the impact of grinding on workpiece accuracy.

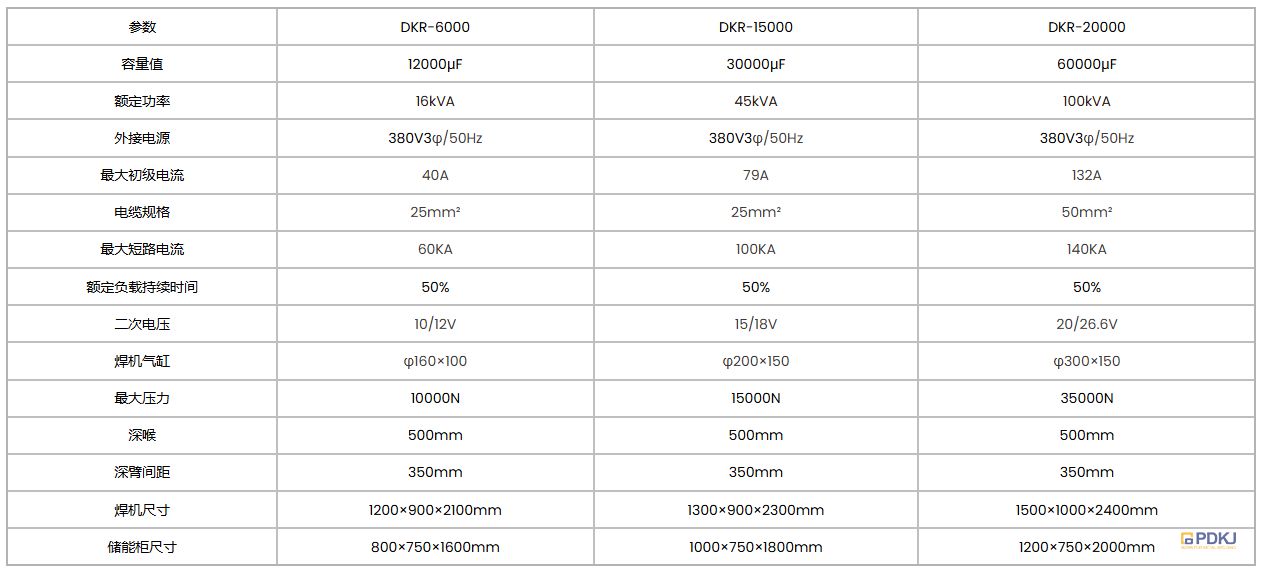

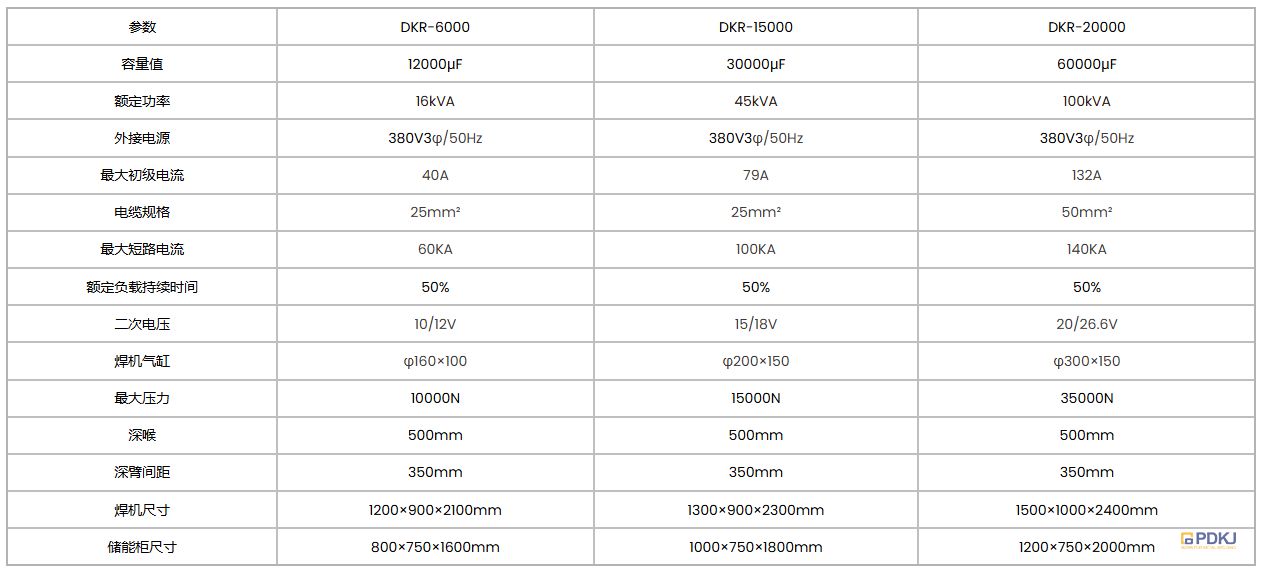

Welding Machine Parameters

Ⅳ Win - Win Cooperation: Making Metal Welding Effortless

During the equipment delivery process, the PDKJ team provided full - time follow - up: in the early stage, they assisted the customer in conducting process tests and optimizing welding parameters; in the middle stage, they completed the equipment installation and debugging on - site, ensuring seamless integration with the customer's existing production line; and in the later stage, they provided specialized training for the operators to help them get up to speed quickly.

During the trial period, the stable performance of the equipment exceeded the customer's expectations —— the weld point pass rate was significantly improved, the rework rate was greatly reduced, and the production efficiency was noticeably increased compared to before. At present, the customer has placed additional orders and plans to promote PDKJ's energy - storage spot welding machine to more body welding stations to deepen the cooperation between the two parties.

Purchase Invitation

If you are facing issues such as fluctuating welding quality, complicated procedures, and difficulties in production adaptation, whether you need to weld hot-formed steel nuts, automotive bumper beams, body connectors, battery tray fasteners, or welding requirements involving stainless steel, aluminum alloy, copper alloy, etc., in the aerospace and energy storage equipment industries, please feel free to contact us, Guangdong PDKJ Automation Technology Co., Ltd. —— With our professional technical team, high-quality welding equipment, and comprehensive service system, we can provide you with the most suitable welding solutions. Let PDKJ become your reliable partner on the welding journey. Together, we can tackle welding challenges, enhance product quality and production efficiency, and boost the development of your enterprise. PDKJ, your welding expert at hand, is looking forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713