Delivery Case of PDKJ Special Aircraft

In the automotive world, crash beams serve as a “critical shield” for occupant safety, and their weld quality directly determines passive-safety performance. Recently, PDKJ drew on its deep know-how of automotive manufacturing to engineer a tailor-made seam-welding machine for an automaker in Xi’an. From initial briefing through design to final shipment, the entire process took only 50 days, successfully eliminating the twin pain points of speed and quality in high-strength-steel crash-beam welding.

1. Customer and Project Background

The Xi’an automaker specializes in high-strength-steel crash beams that require multi-layer stack welding, placing extreme demands on continuity, strength and stability. Traditional production had two stubborn headaches:

Poor continuous-welding speed – existing machines couldn’t keep up with the high duty cycle needed for hot-formed steel, so takt times dragged and large-volume orders slipped.

Elusive weld quality – every spot had to be splash-free, free of burn-through, and stronger than the base metal, yet conventional power sources suffered current drift and rapid electrode wear. Re-work rates soared, costs rose and deliveries were delayed.

To break the bottleneck, the customer urgently needed equipment purpose-built for hot-formed steel and flexible enough to match its exact welding recipe. Guided by its mission “Make welding any metal product simple,” PDKJ—backed by a long track record in automotive welding—was the partner of choice.

2.Highlights of Customized Welding Machine Equipment

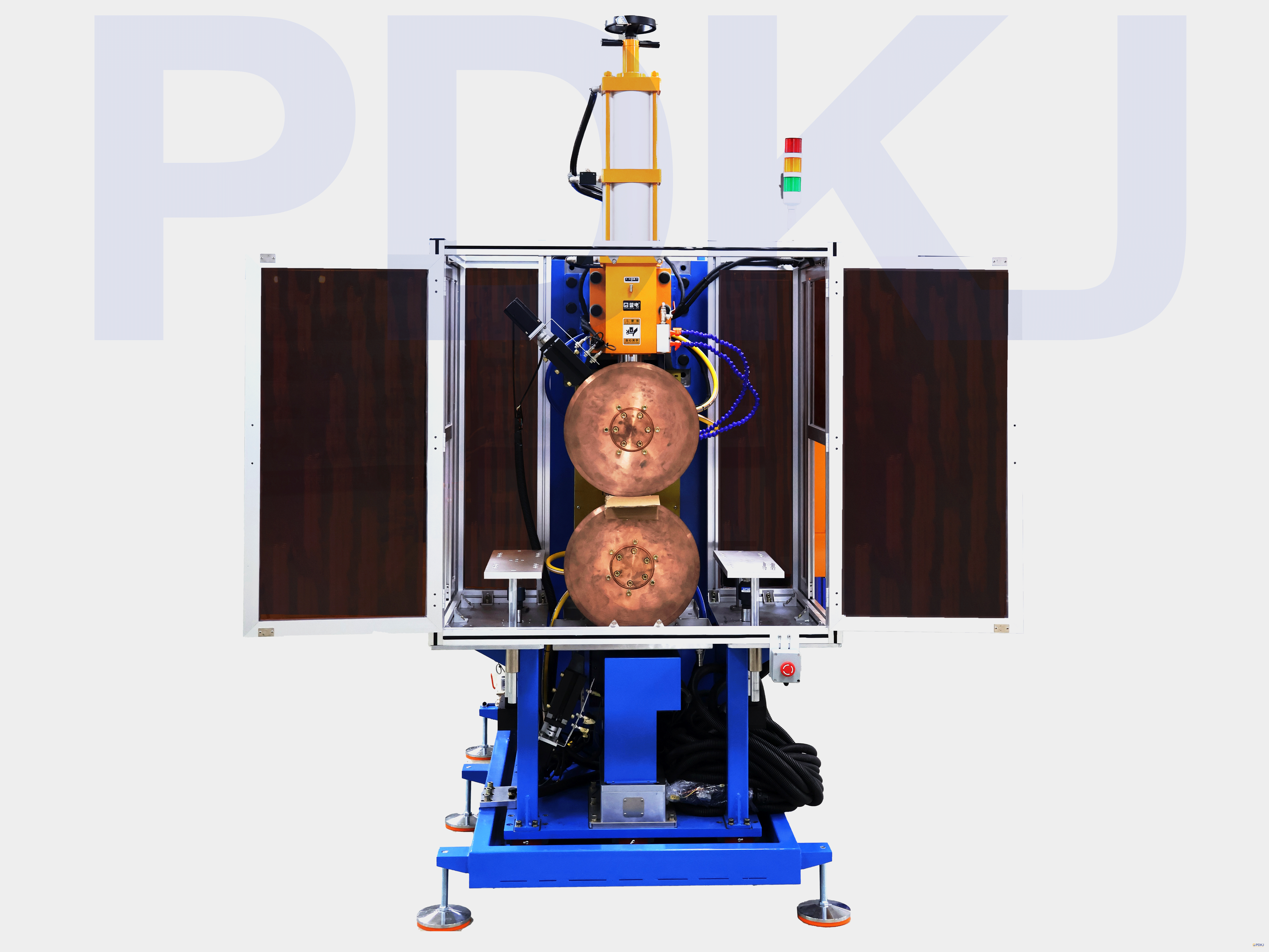

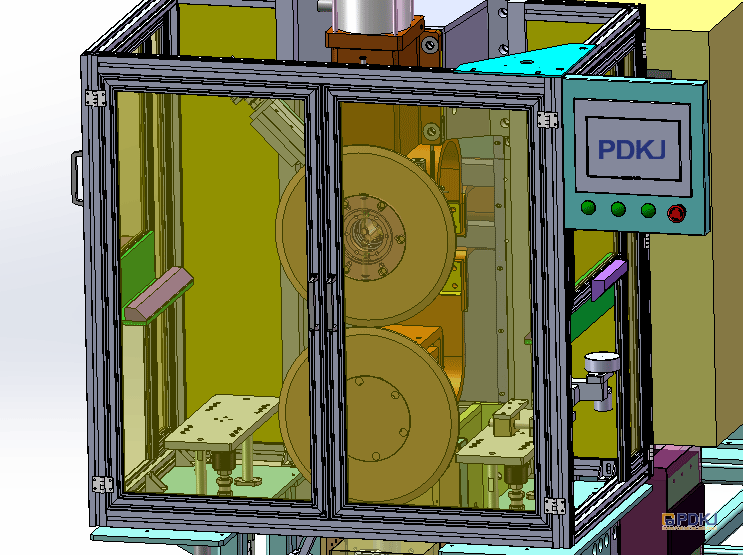

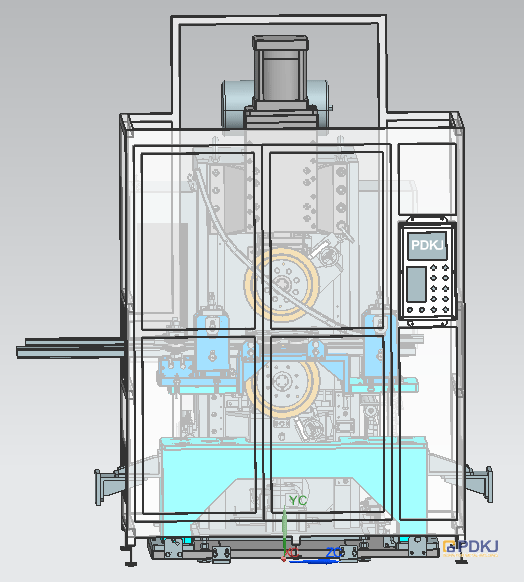

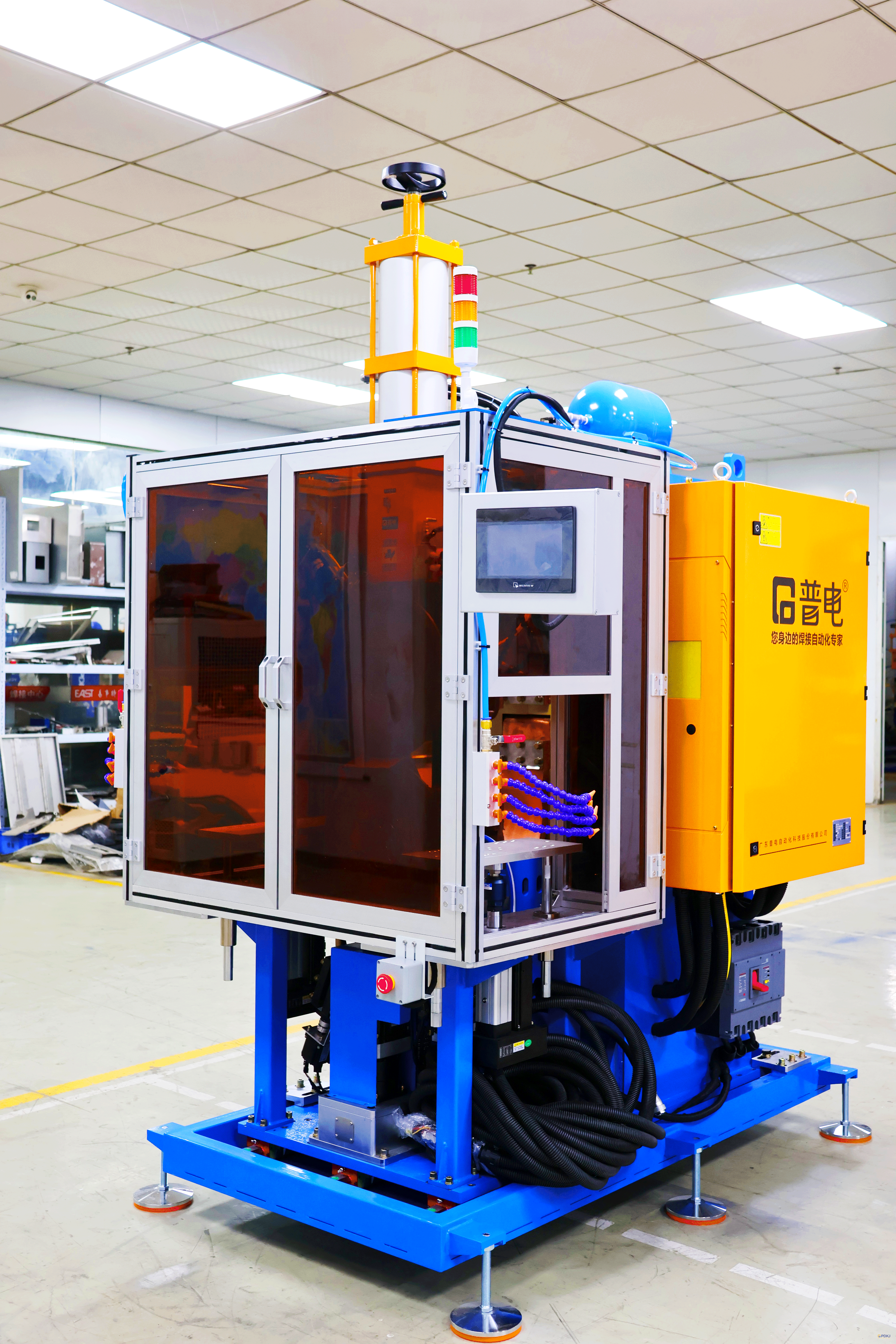

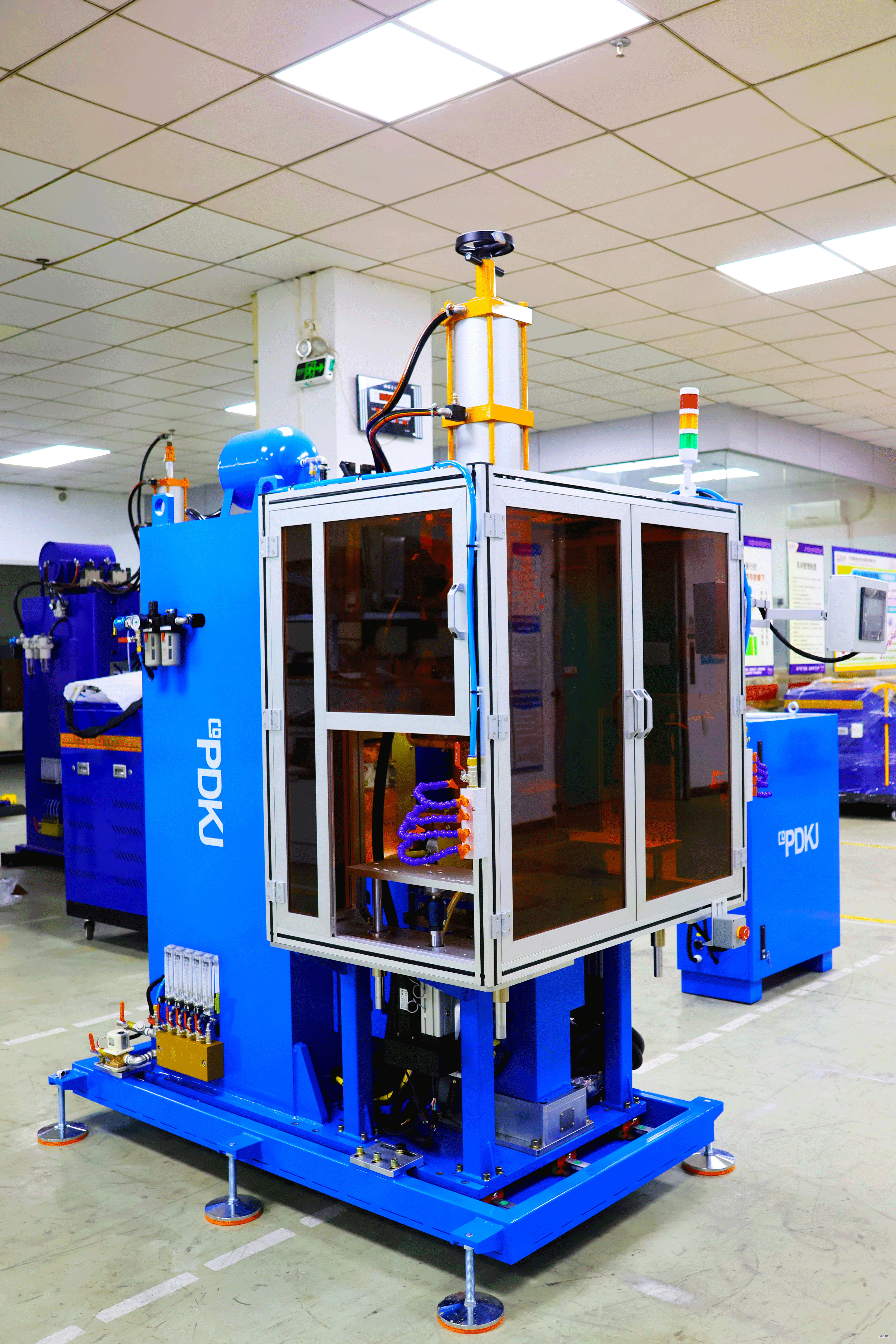

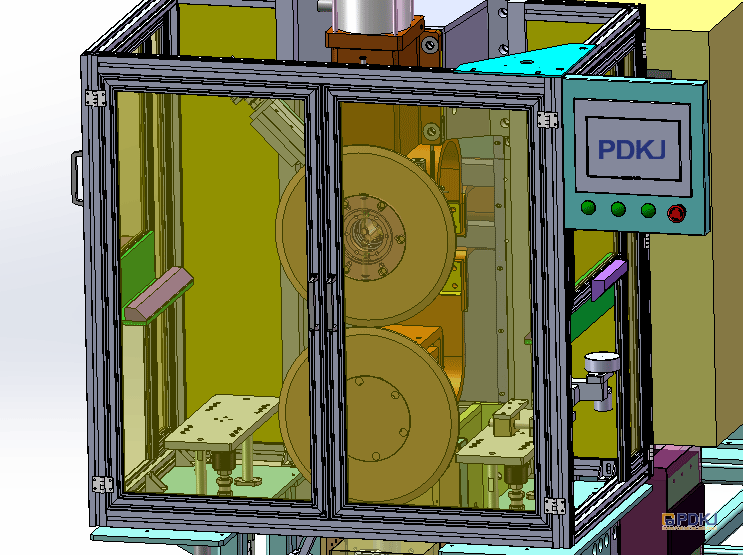

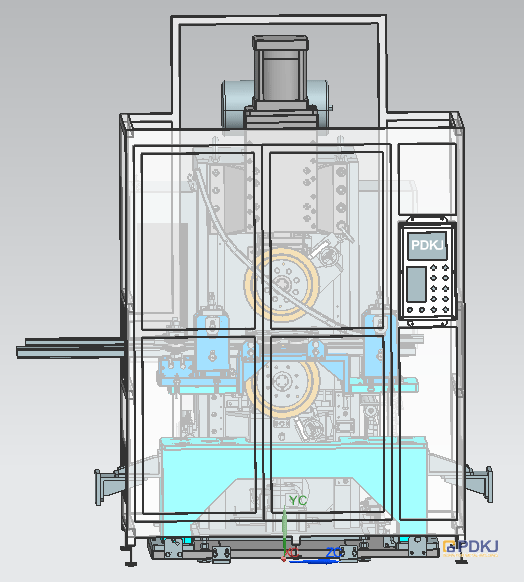

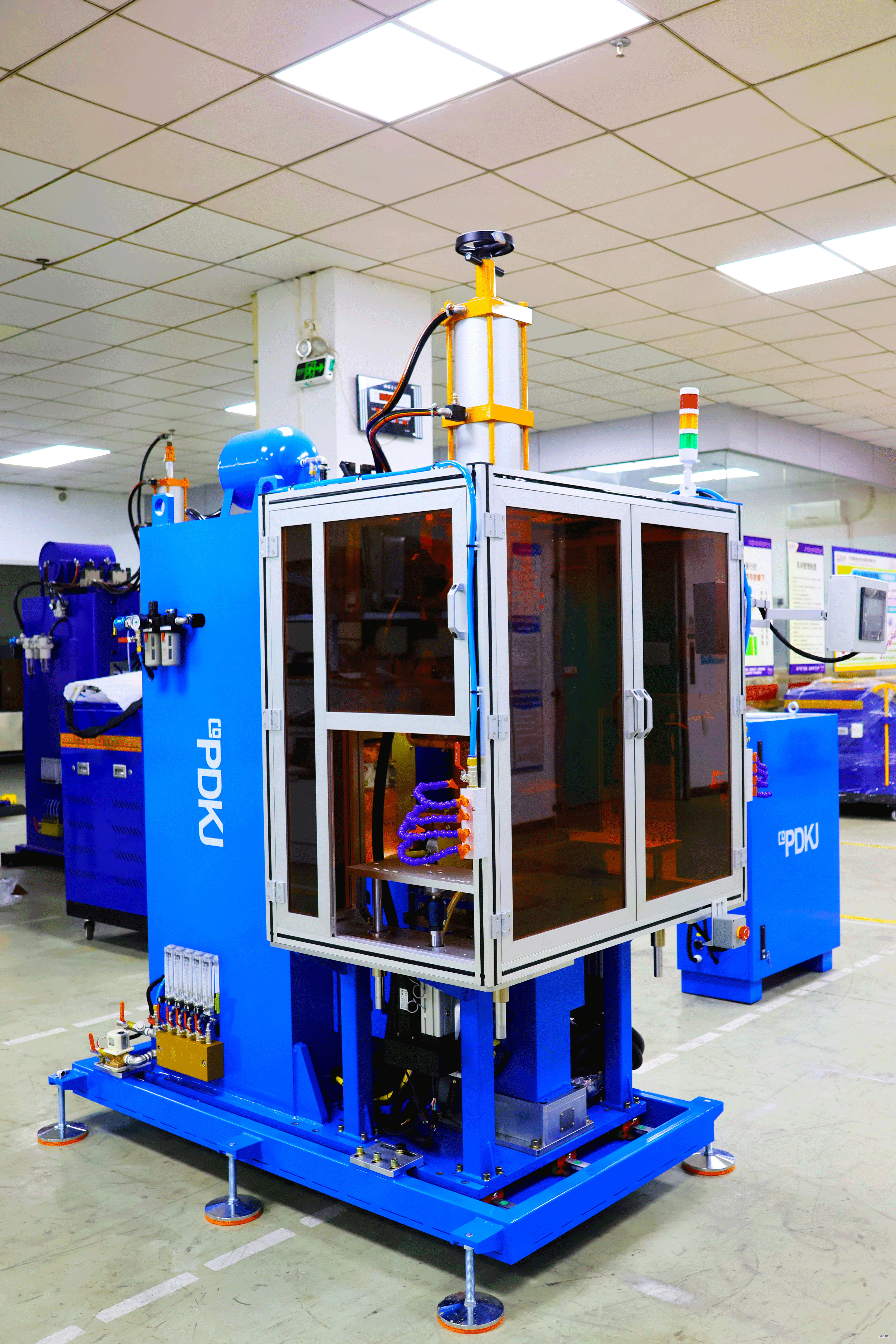

To meet the customer’s specific requirements, PDKJ’s R&D team has developed a dedicated vertical medium-frequency inverter seam-welding solution built on the core principles of “precise adaptation and high-efficiency stability,” comprehensively addressing every customer pain point:

1. High-speed continuous welding aligned with production targets

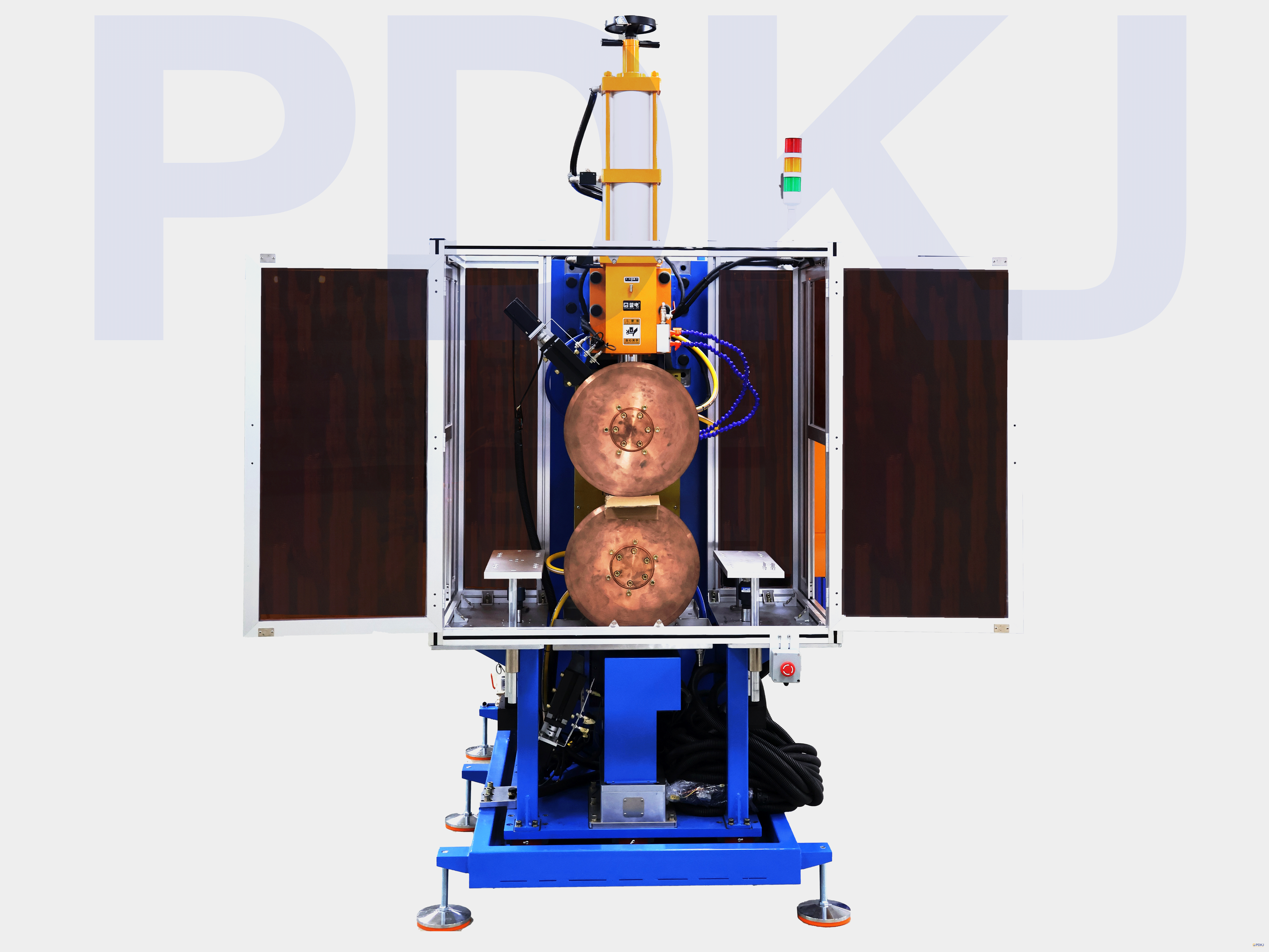

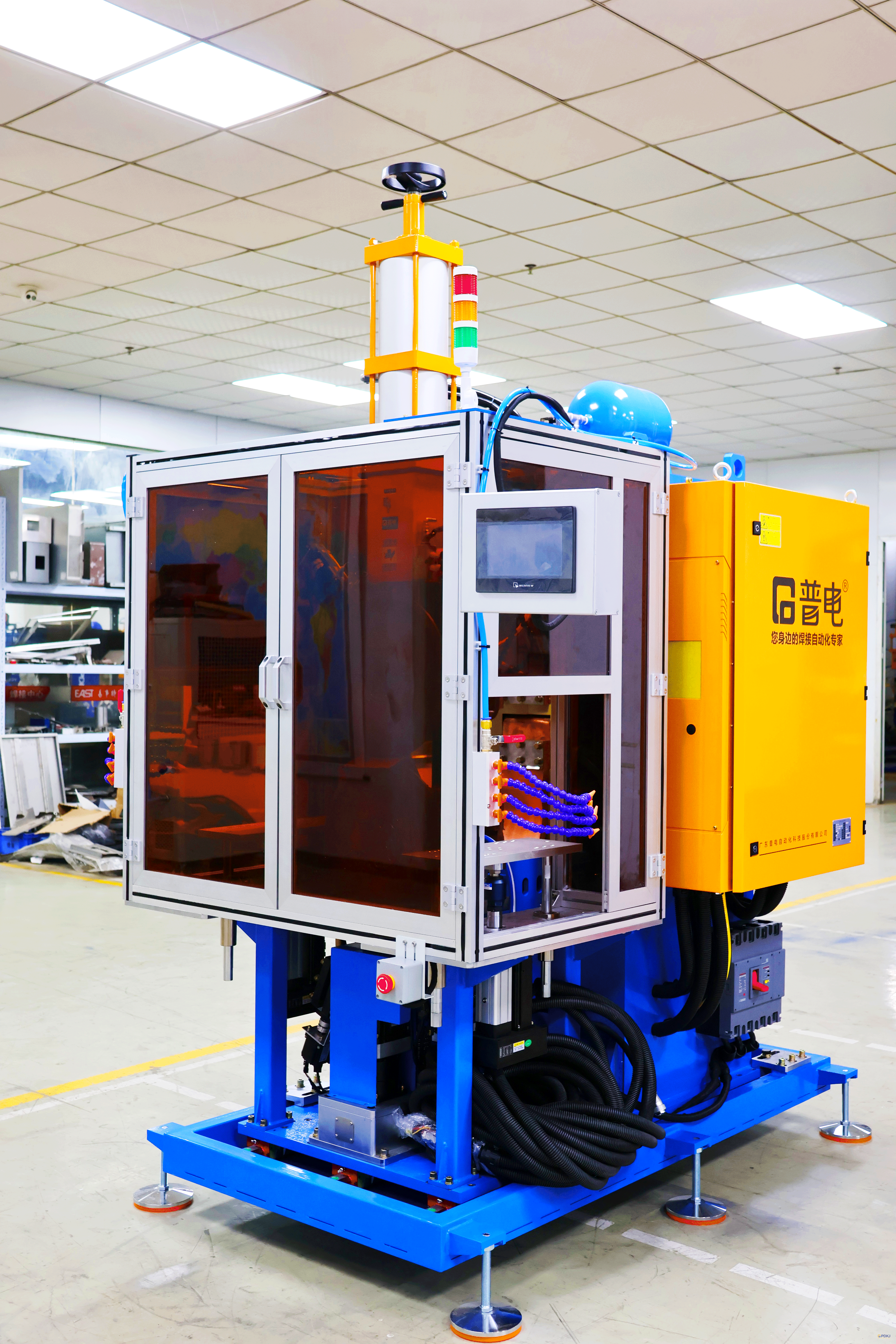

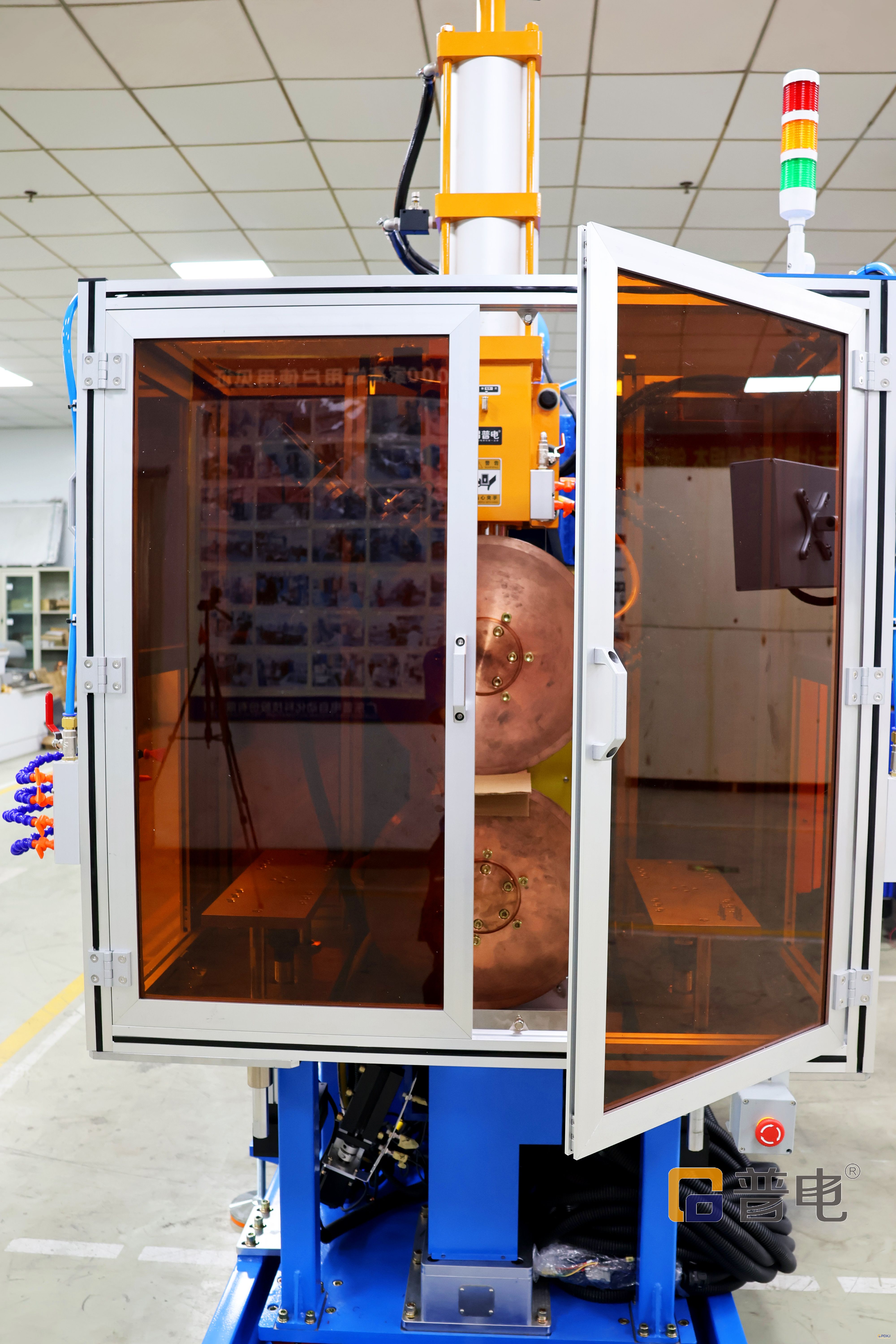

Designed for high-volume takt demands, the system adopts an automated continuous spot-welding architecture. A pair of rotating roller electrodes apply controlled pressure and current to the bumper beam, creating a reliable lap joint between inner and outer metal layers. Optimized power delivery and control logic guarantee a smooth, uninterrupted welding process, substantially increasing the number of welds per unit time and easily satisfying the customer’s capacity goals—eliminating the “low efficiency, slow takt” drawbacks of traditional equipment.

2. Precision quality control + durable design for superior weld integrity

To achieve the technical requirement that “weld strength must exceed base-metal strength,” PDKJ exercises rigorous oversight of critical components and functions:

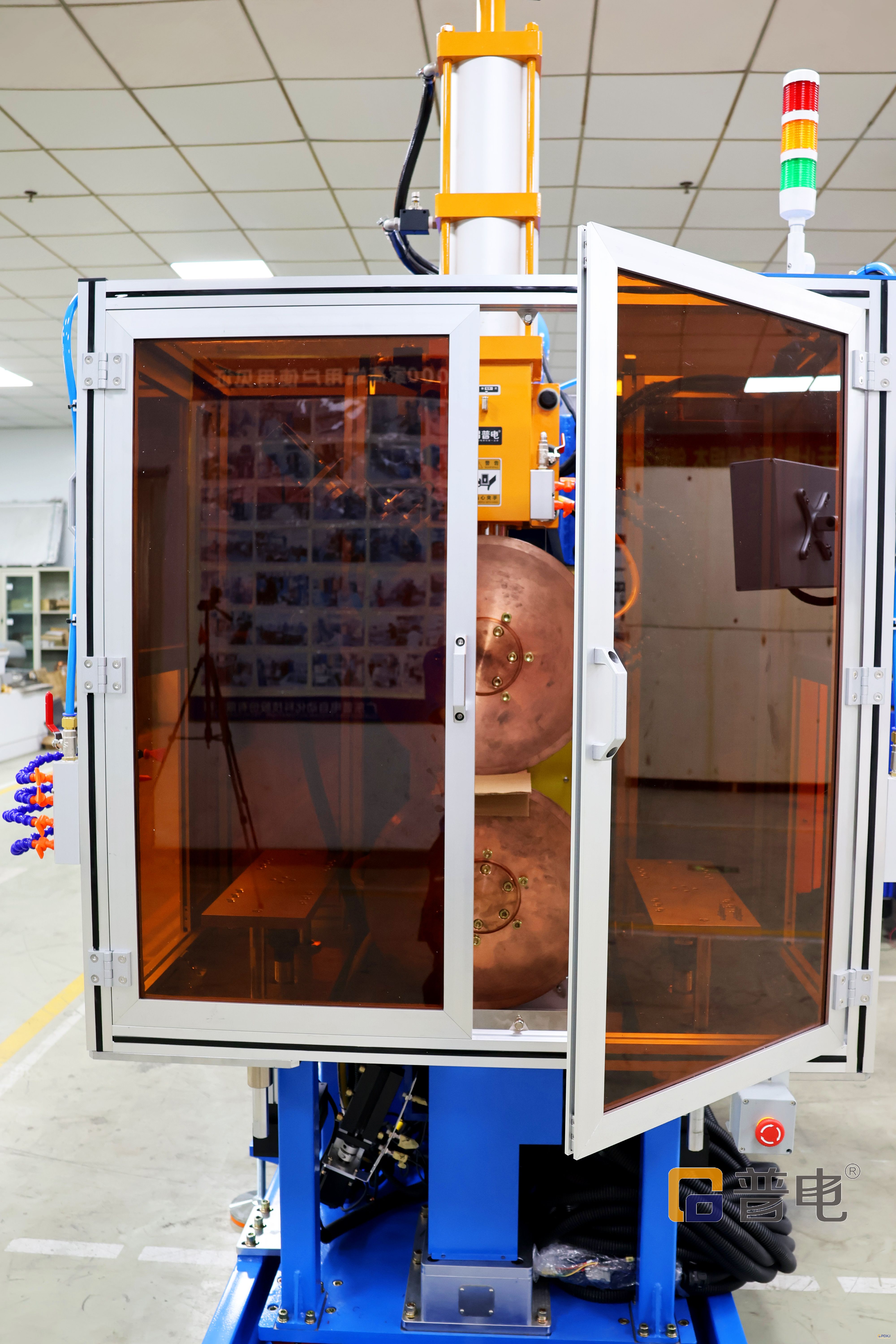

• Seam-welding wheels are fabricated from a proprietary, highly wear-resistant, high-conductivity alloy.

• A premium, silver-layered, sealed copper busbar assembly ensures stable current transmission, preventing spot defects caused by uneven conductivity.

• Servo-driven automatic dressing supports both stop-and-go and on-the-fly dressing modes, adjustable to the welding rhythm, keeping the wheels in optimal condition at all times and eliminating quality fluctuations from electrode wear—ensuring freedom from spatter or burn-through.

3. Flexible adjustment + comprehensive safety for sustained production

Anticipating potential changes in bumper-beam specifications, the machine is designed with ample adjustment range: the upper wheel moves vertically, the lower wheel offers electric jog adjustment, and the base can shift longitudinally via bolted rails—allowing model changeovers without major retrofits and drastically shortening setup time. In addition, an integrated safety system halts welding if pneumatic pressure is insufficient and immediately stops the machine if cooling-water flow drops below threshold, preventing quality degradation from abnormal operating conditions and safeguarding overall line stability.

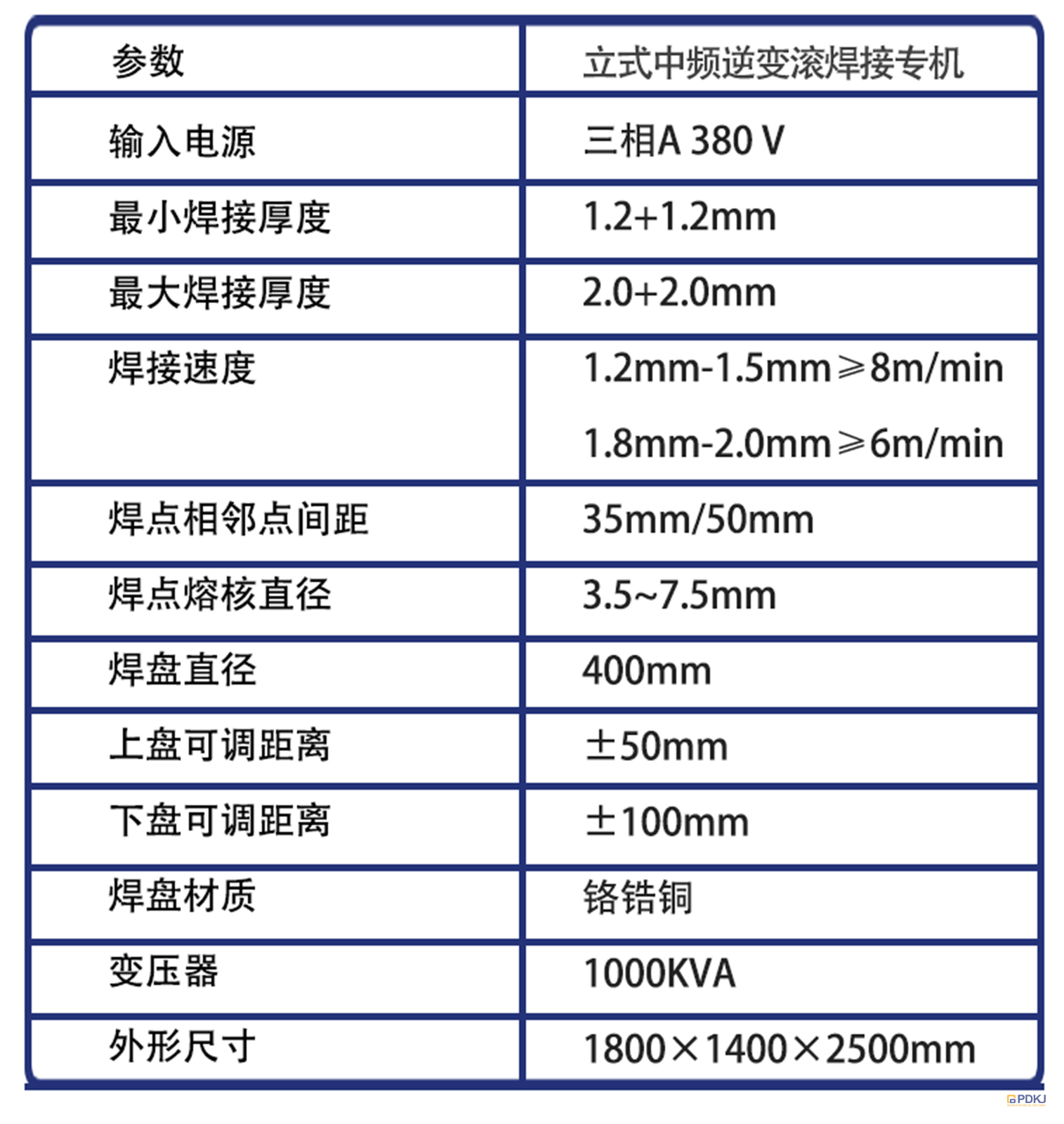

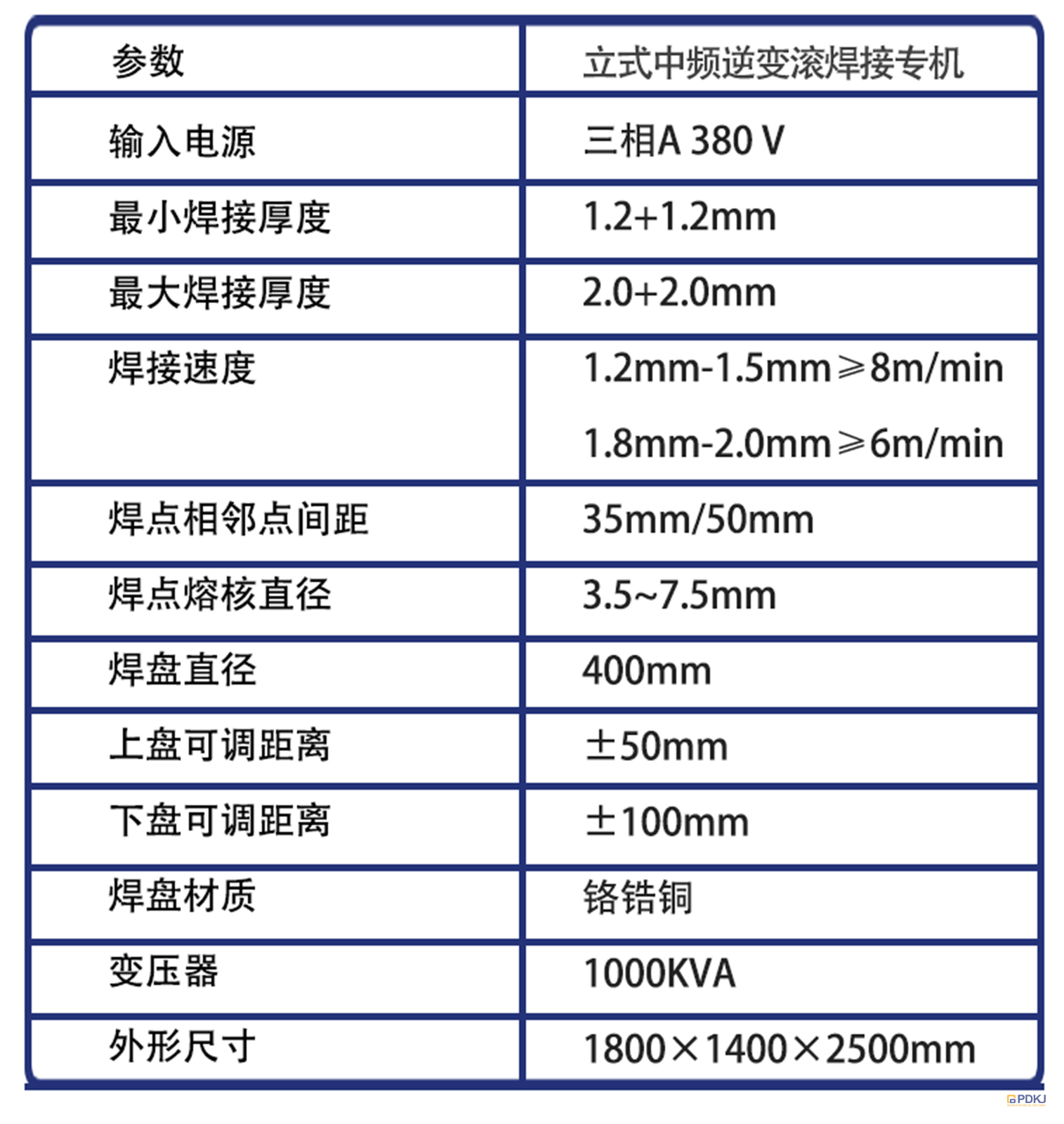

Welding machine parameters

3. Project achievements

For automotive manufacturers, equipment lead time directly dictates order-delivery schedules. Centering on customer needs, PDKJ streamlines the entire project flow: from upfront parameter verification against technical documentation, through mid-stage component fabrication and assembly, to final on-site commissioning and factory acceptance. The complete cycle is completed in just 50 days—almost 25 % faster than the industry average—enabling customers to restore high-volume production quickly and seize critical market-delivery windows.

Once the equipment went live, the customer saw immediate results: welding speed stabilized at the required rate, dramatically boosting line capacity, and post-weld bumper beams passed rigorous testing—impact resistance fully met and even surpassed expectations—delivering rock-solid safety assurance.

From standardized machines to tailor-made turnkey solutions, PDKJ remains devoted to the mission of “Make Metal Welding Easy for the World.” Deeply rooted in the welding field, we keep innovating to offer manufacturing industries ever more efficient, intelligent, and reliable welding solutions.

Customized service invitation

Unlock welding possibilities immediately

Whether you are in automotive, home appliances, telecommunications, or any other industry—and whether you need to weld high-strength steel, galvanized sheet, aluminum alloy, or any other material—PDKJ can engineer a dedicated welding system precisely tailored to your part dimensions, production targets, and quality standards.

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713