Guangdong Pudian Automation Technology Co., Ltd. successfully delivered a "Robotic Laser Welding Workstation" to an electrical equipment manufacturing company in Zhejiang Province. This company has been deeply involved in the intelligent power distribution field for over two decades. Its core products cover metal distribution boxes, industrial cabinets, and intelligent complete sets of electrical equipment, widely serving key scenarios such as data centers, industrial control, and new energy. Its products are also exported to Southeast Asia, Europe, and the Americas, demonstrating a mature technological and market foundation in the intelligent power distribution field.

The "Robotic Laser Welding Workstation" and its customized components provided by PDKJ successfully solved the company's challenges in precision control, efficiency improvement, and welding of complex structures in the production of distribution boxes and cabinets. The solution not only helps the customer solidify its high-end electrical equipment production capacity and achieve intelligent manufacturing upgrades, further consolidating its competitiveness in overseas markets, but also provides a solid guarantee for the power supply needs of Industry 4.0, data centers, and other fields, promoting the customer's continued development in the high-end electrical equipment sector.

I. Project Background

As a core industrial belt for intelligent power distribution equipment manufacturing in China, Zhejiang is home to numerous electrical enterprises with technological innovation capabilities. The client in this collaboration is a typical example – possessing advanced production facilities and an experienced R&D team. Their products cover chassis, cabinets, control boxes, charging piles, switch cabinets, terminal boxes, protective covers, cable covers, and other products, with stringent requirements for product precision, structural strength, and appearance consistency.

With the continued growth in domestic and international orders, customers' existing welding processes have gradually revealed three core problems, making them unsuitable for current production demands:

Firstly, the core profiles of customer cabinets are made of high-quality cold-rolled steel plates. Traditional welding, due to uneven heat input control, easily leads to localized overheating and deformation of the plates, directly affecting the assembly accuracy of the cabinets.

Secondly, insufficient welding precision is a prominent issue. Manual welding operations rely on experience, resulting in inconsistent weld spacing and weld penetration that does not meet standard requirements, directly impacting the overall structural stability of the cabinets.

Low welding efficiency has also become a key constraint on production. Faced with a monthly production capacity demand of thousands of cabinets, the existing welding production pace cannot keep up with the order growth rate. This not only leads to a continuously tight order delivery cycle but also exacerbates the capacity gap during peak production seasons, directly affecting customers' ability to fulfill orders.

To overcome production bottlenecks, customers urgently need a fully automated welding solution that can adapt to various types of distribution boxes and cabinets.

II. Customer Welding Needs

As a company focusing on high-end electrical equipment manufacturing, our customers' welding needs are closely aligned with product characteristics, quality standards, and production capacity targets. These can be summarized into four main areas:

Material Compatibility Needs: The core of the cabinet uses high-quality cold-rolled steel plates. The problem of uneven heat input during traditional welding, leading to plate deformation, needs to be addressed to ensure the cabinet's structural flatness meets assembly precision requirements after welding.

Complex Structure Welding Needs: Our products encompass various types, including wall-mounted, floor-standing, and network cabinets. Welding blind spots exist in areas such as corner joints and internal cavities. Specialized equipment is needed to adjust workpiece angles to achieve automated welding with no dead angles.

Quality Compliance Needs: Welding strength must meet standards, eliminating incomplete welds and penetrating welds to ensure long-term operational stability of the cabinets.

Customized Fixture Needs: Due to significant differences in the contours of different cabinets, specialized fixtures are required for precise clamping. Adjustable positioning devices and protective components are also necessary to handle complex welding scenarios and ensure operational safety.

To change the status quo, the client investigated several equipment manufacturers. After learning about Pudian's technical expertise in welding, reliability, practical value, and other aspects, the client took the initiative to seek cooperation and hoped to obtain a customized welding solution.

III. Highlights and Advantages of PDKJ Welding Machine

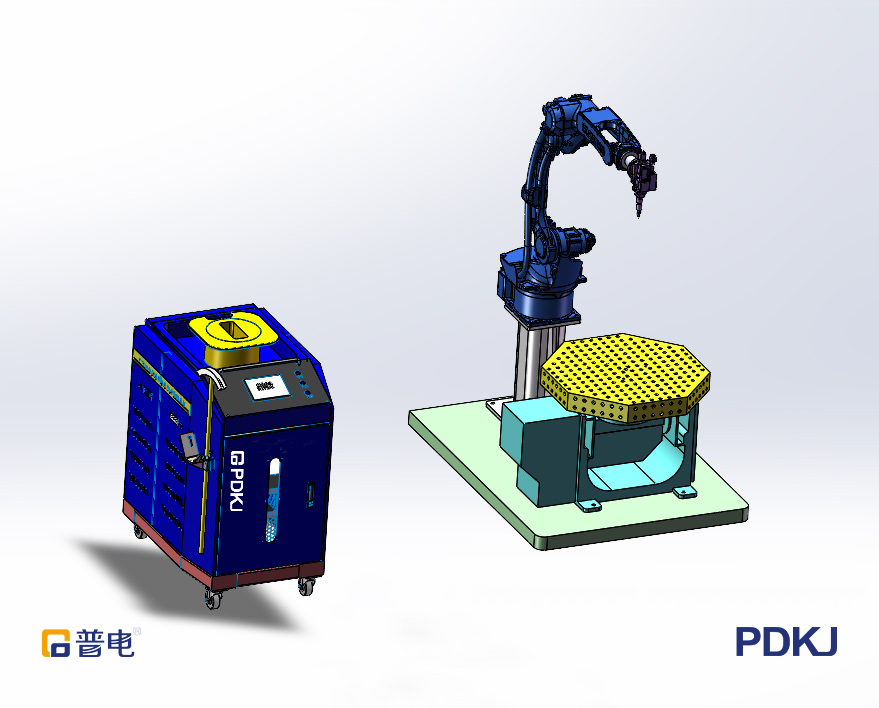

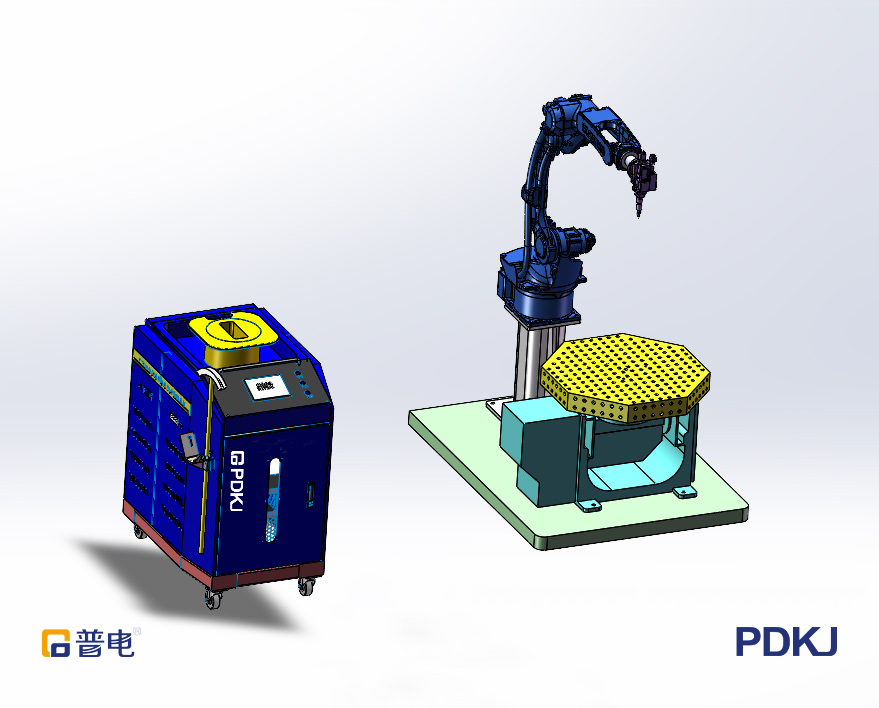

Addressing the material characteristics, diverse welding needs, and mass production scenarios of customers' power distribution boxes and cabinets, the PDKJ R&D team developed a "robotic laser welding workstation" as its core, complemented by a high-precision servo positioner, customized product fixtures, and high-temperature resistant baffles. This forms a complete "core equipment + auxiliary components" solution, precisely tailored to the customer's production requirements.

1. Automation + Customized Fixtures: Uncompromised Weld Quality

Customized fixtures feature multi-point precise positioning to prevent workpiece displacement during welding. The automated welding robot operates stably along a preset trajectory, requiring no manual intervention. The penetration depth and width of each weld remain consistent, eliminating quality variations caused by human error.

2. Laser + Robot + Positioner: Completely Overcoming Welding Blind Spots

The workstation's 6-axis robot possesses multi-dimensional flexible operation capabilities. Paired with a customized high-precision positioner, it can actively "flip" areas such as cabinet corners and deep internal cavities to the robot's optimal welding perspective. Laser welding is precisely focused, resulting in smooth, splatter-free welds with full, stable weld nuggets, eliminating the need for manual re-welding. This fully meets the structural strength and aesthetic requirements of the cabinets, aligning with overseas order quality standards.

3. Preset Parameters + Easy Operation: Even Beginners Can Weld Standard Welds

The workstation supports pre-setting welding parameters (laser power, speed) and positioner movement trajectories for different cabinet sizes into the system. After short-term training, novice welders can simply select the model on the operation screen to automatically call up the program. This eliminates the need for experienced welders, enabling stable, aesthetically pleasing, and robust welds, solving customers' problems with finding welders and inconsistent quality.

4. Protective baffles + continuous operation improve batch production efficiency

Automated operation reduces direct human contact with the welding area. Combined with the safety protection of protective baffles, it reduces labor costs and avoids the harm to workers caused by high temperatures and strong light. The automated control system can realize unattended operation of the entire welding process. With the "welding-adjustment synchronization" function of the positioner and the high operating speed of laser welding, it can easily meet the batch production capacity demand of thousands of units per month for customers and reduce production downtime.

IV. Win-Win Cooperation: Make Metal Welding Easy for the World

PDKJ adheres to the philosophy of "Make Metal Welding Easy for the World," providing customers with one-stop support from solution design to post-maintenance.

In the initial stages, we delved into the customer's production site, optimizing the placement of workstations and positioners based on the existing production line layout to ensure seamless integration with stamping and assembly processes, minimizing workpiece transfer time. After equipment arrival, professional engineers completed installation and commissioning within 24 hours, simultaneously providing specialized training to the operation and maintenance teams (covering workstation operation, daily positioner calibration, and fixture and baffle replacement and maintenance). We also provide 24/7 remote technical support; in case of minor equipment malfunctions, technicians can quickly troubleshoot and resolve issues remotely, avoiding prolonged production downtime.

To date, the workstations have been operating stably for several months, resulting in significant positive changes in the customer's production: Welding yield has greatly improved, and production losses due to welding issues have significantly decreased; order delivery has become more stable, effectively alleviating delivery pressure caused by insufficient capacity during peak seasons; overseas customers' acceptance of the product's welding quality has further increased, leading to stronger repeat purchase intentions and successfully expanding new overseas cooperation opportunities.

Based on the positive results of the collaboration and the stable performance of the equipment, the customer has initiated the planning of a new production line, plans to purchase additional workstations with the same configuration, and simultaneously address the customized fixtures and equipment development needs for the new model cabinet. The cooperation between the two parties has deepened from single project delivery to long-term technical collaboration!

PDKJ Automation Technology Co., Ltd., a professional manufacturer of welding equipment, boasts nearly 20 years of industry experience and has successfully delivered solutions for over 6,500 welding workpieces. The company consistently adheres to a technology-driven innovation strategy, providing customers with high-quality, high-performance welding automation equipment.

Our product line includes:

Spot Welding Equipment: Medium-frequency inverter spot welding machines, AC spot welding machines, energy storage spot welding machines, platform-type non-marking spot welding machines

Laser Welding: Robotic laser welding workstations, handheld laser welding machines, galvanometer laser welding machines

Welding Specialty Machines: Various customized welding specialty machines, automated welding production lines

Welding Accessories: Welding electrodes, transformers, controllers, etc.

......

Purchase Invitation

If you are struggling with welding issues related to high and low voltage electrical appliances, metal distribution boxes and cabinets, new energy vehicle charging piles, stainless steel wall-mounted enclosures, floor-standing metal cabinets, metal junction boxes, sheet metal enclosures, and other similar products, please contact Guangdong Pudian Automation Technology Co., Ltd. immediately. Our professional technical team, high-quality welding equipment, and comprehensive service system will provide you with the most suitable welding solutions. Let PDKJ be your reliable partner on your welding journey, working together to overcome welding challenges, improve product quality and production efficiency, and help your company thrive. PDKJ, your welding expert, looks forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713