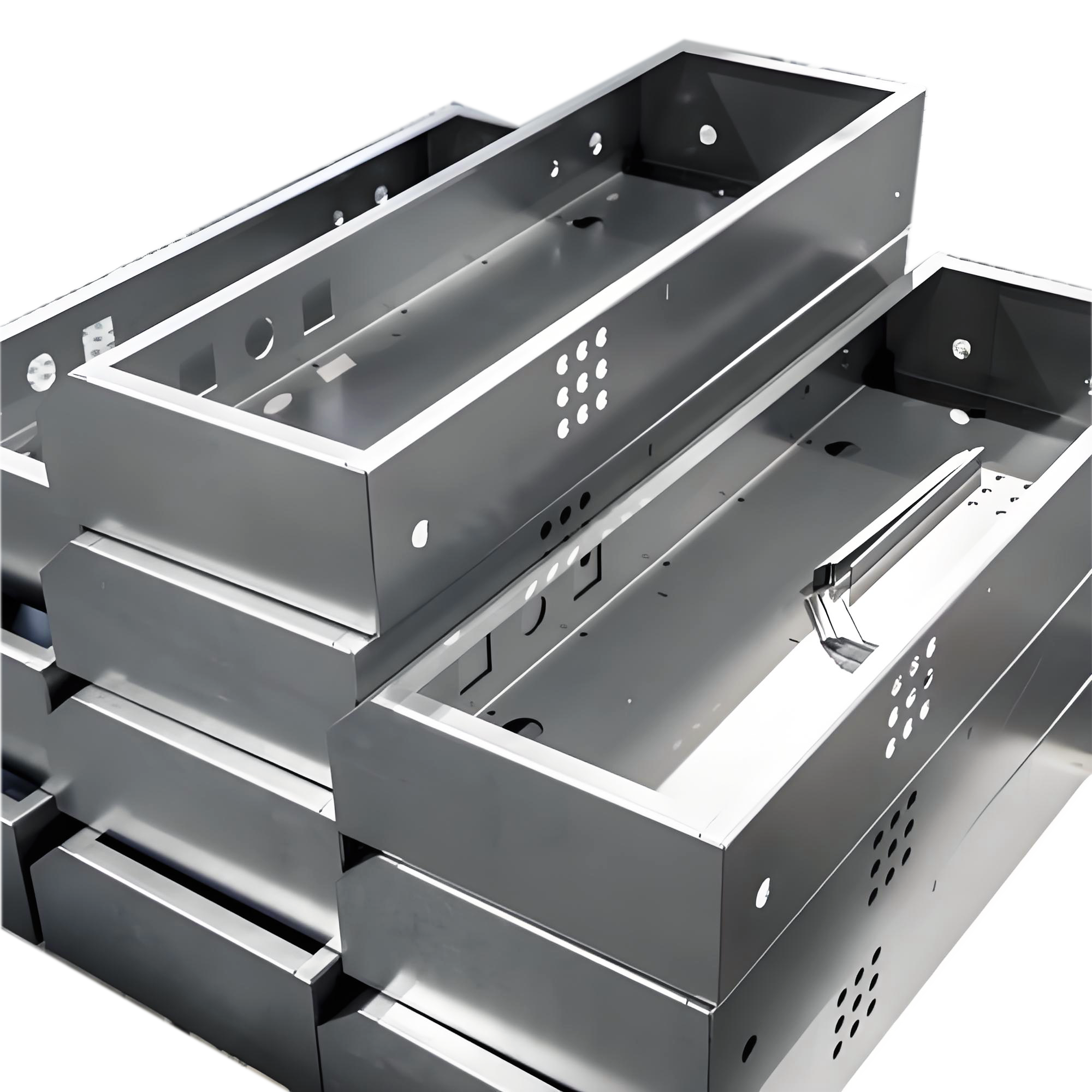

Product Display

Chassis Cabinet

When welding large sheet metal materials, many enterprises are caught in a dilemma: they need to ensure stable and reliable welding quality while also achieving a seamless and aesthetically pleasing surface. At the same time, they must improve efficiency to match the pace of large - scale production while strictly controlling the defect rate. These seemingly contradictory requirements not only affect the appearance and performance of the product but also directly impact the company's production costs and market competitiveness, becoming a key bottleneck in production. The successful delivery of PDKJ's Platform - Type Medium - Frequency Inverter Spot Welder (Dual - Gun) to a customer in the Shenzhen smart communication equipment industry and its role in bringing technological innovation to the welding of cabinet casings provides a solution to this problem. Let's explore the unique technologies and advantages of this equipment that enable it to achieve such breakthroughs.

Ⅰ Project Background

Since its establishment, the Shenzhen - based customer has always focused on the research and development as well as production of material - forming equipment (such as die - casting machines, injection - molding machines, and CNC machining centers). Its products are widely used in data centers, power systems, communication base stations and other fields. It is a globally renowned one - stop intelligent solution provider. In its equipment production, the cabinet shell plays a key role in protecting internal components and ensuring the stable operation of the equipment. Therefore, it has three core requirements for the welding process:

First, strong material compatibility to meet the welding needs of different materials such as stainless steel and carbon steel;

Second, high - quality appearance with no obvious weld point marks on the surface as an external component of the equipment;

And third, accurate structural precision to ensure precise assembly with internal components and avoid affecting the overall performance of the equipment due to dimensional deviations.

Ⅱ Customer Welding Production Pain Points

Before the introduction of the PDKJ Dual - Gun Spot Welder, the customer's cabinet shell welding process had long faced three core challenges that severely affected production efficiency and product quality:

Poor quality stability: Due to the complexity of the welding process, traditional welding equipment is prone to problems such as virtual welding and missed welding during the welding process. This leads to unstable product quality, increasing the defect rate and rework cost.

In response to these pain points, the customer urgently needs a device that can achieve seamless welding, improve welding efficiency, and ensure stable welding quality.

Ⅲ Highlights And Advantages Of PDKJ Welding Machine

The PDKJ team, through in - depth research in the early stage and in combination with the customer's core requirements of "seamless welding + efficient product changeover + stable precision," ultimately customized and delivered the DB - 170W Platform - Type Medium - Frequency Inverter Spot Welder (Dual - Gun) to inject new kinetic energy into the customer's production line.

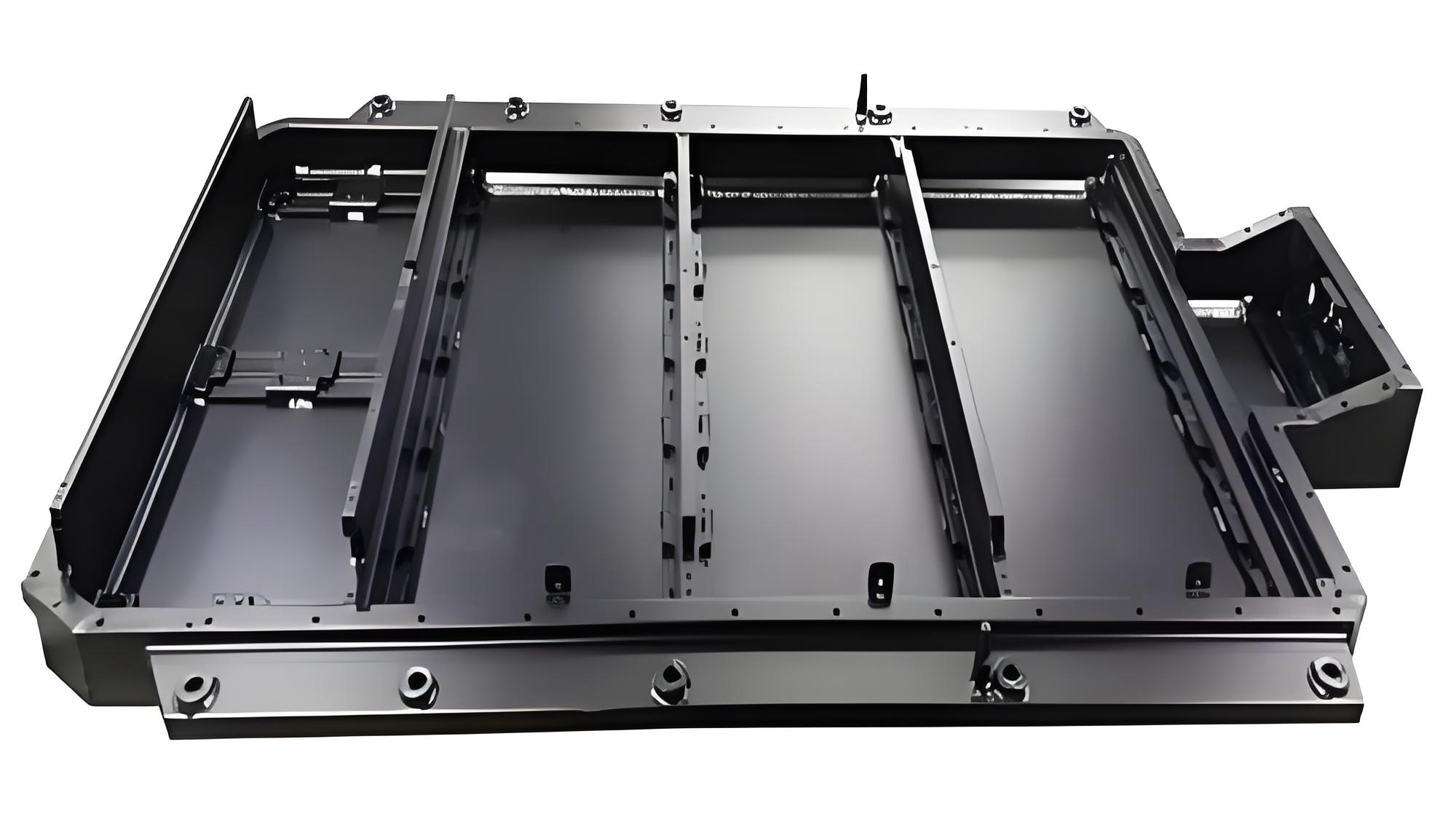

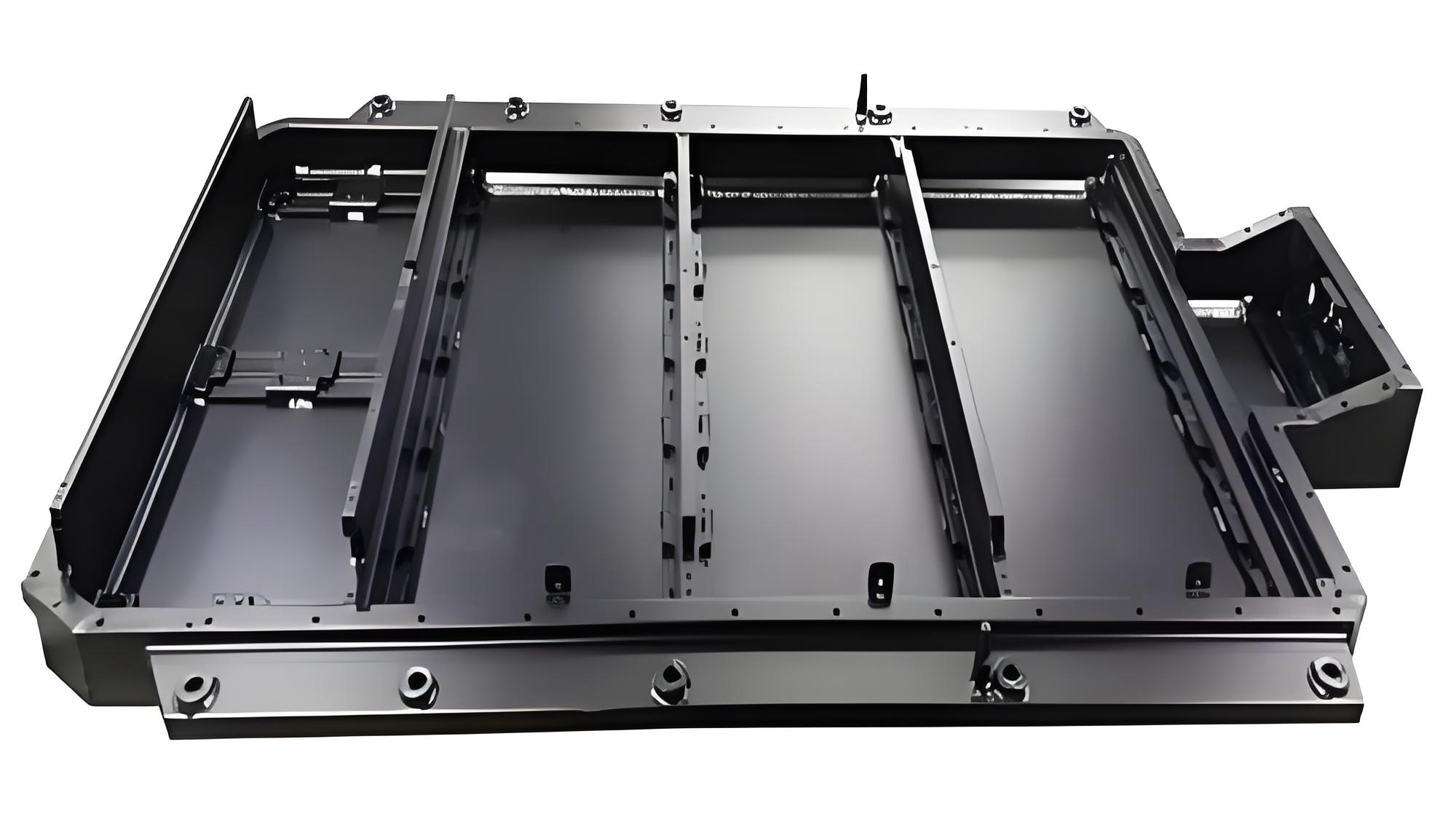

1. Dual - Gun + Large - Platform Design, Overcoming Large - Size Welding Challenges

Dual - gun synchronous welding: The 390 - mm - long dual - reclining welding guns, paired with a 360° multi - jointed robotic arm, can simultaneously weld both sides or the upper and lower edges of the cabinet shell. The wide coverage eliminates the need for manual workpiece movement, fundamentally avoiding assembly deviations.

Electrically adjustable large platform: The customizable platform (1000×800mm, with a height of 700 - 800mm that can be electrically adjusted) can stably support large - size cabinet shells, ensuring that the workpiece does not wobble during welding. The diagonal deviation and seam gaps of the cabinet shell are all controlled within the customer's assembly requirements, significantly improving subsequent assembly efficiency.

2. Seamless Welding, Eliminating Secondary Processing

The equipment uses direct - current smooth output + a chromium - zirconium - copper welding platform. The stable current output without impact concentrates the heat in the weld - core area during welding, effectively avoiding surface oxidation or the formation of weld craters. Meanwhile, the chromium - zirconium - copper - based welding platform has excellent heat - dissipation efficiency, which can quickly disperse the residual heat generated after welding, reducing local deformation of the cabinet shell. In practical applications, the customer's cabinet shell has no obvious weld marks on either side, with a smooth and flat surface that fully meets the "grinding - free direct assembly" requirement. This completely eliminates the need for subsequent processing steps, reducing costs and avoiding quality risks associated with grinding.

3. Precise Matching of Multiple Materials to Ensure Welding Stability

Equipped with a computer - based closed - loop control system, the equipment can real - time adjust the three core welding parameters: current, time, and pressure. For stainless - steel cabinet shells, a low - heat, short - duration welding mode is used to prevent surface discoloration. For carbon - steel cabinet shells, constant electrode pressure ensures weld - core depth, guaranteeing a strong welding joint. The welding quality of both materials can stably meet the customer's precision standards, significantly reducing rework rates and greatly enhancing the stability of the welding process.

4. Intelligent Operation + Durable Structure, Compatible with Automated Production Lines

The equipment is equipped with an LCD touch screen that can store multiple sets of welding parameters (covering all cabinet shell specifications of the customer). When switching products, parameters can be retrieved with a single click, eliminating the need for repeated adjustments and greatly reducing product - changeover time. The machine body is forged from high - strength steel as a single piece, with strong rigidity and outstanding resistance to deformation. Even after long - term operation, the welding parameters can still remain stable, perfectly matching the customer's automated production rhythm and avoiding production - line stoppages caused by equipment failures.

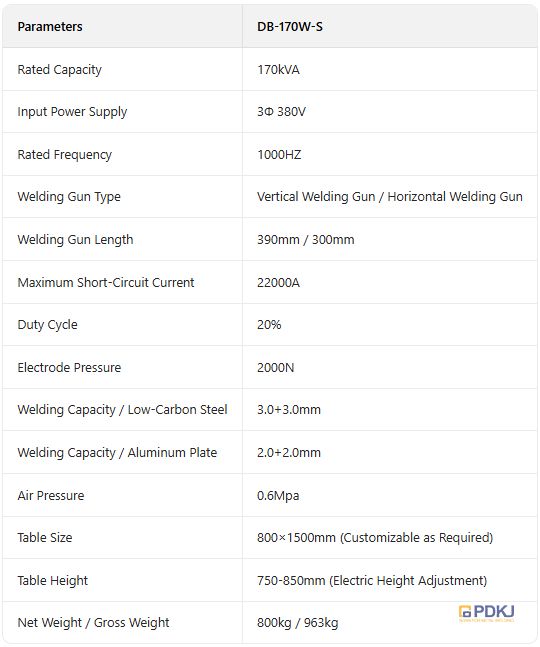

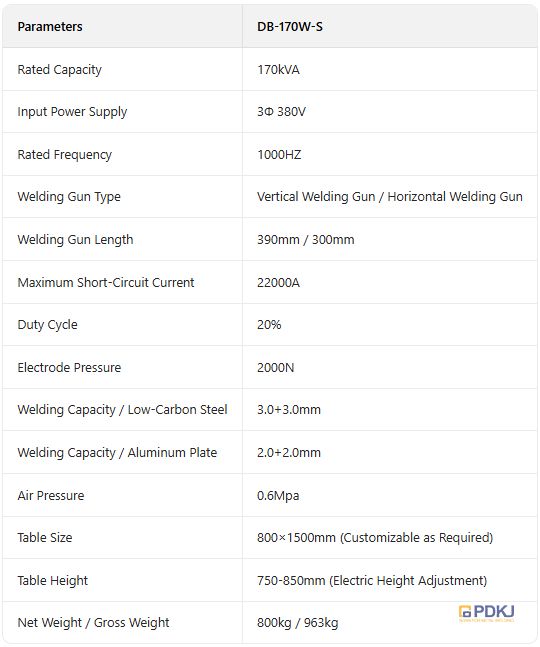

Welding Machine Parameters

Ⅳ Win - Win Cooperation: Making Metal Welding Effortless

During the equipment delivery process, the PDKJ team demonstrated a professional service spirit. From the initial demand communication and process testing to the later stages of equipment installation, commissioning, and operator training, PDKJ followed through the entire process to ensure the rapid implementation and production of the equipment. The customer provided feedback: "Initially, we only introduced one unit with a trial mindset, but it not only solved the welding efficiency issue but also significantly improved the appearance quality, which was of greatest concern to the customer. Recently, we have placed an additional order for two units for the new battery tray production line."

This cooperation is just the beginning of PDKJ's collaboration with customers in the Shenzhen smart communication equipment industry. With its seamless welding technology and flexible customization solutions, PDKJ's welding machines have been widely applied in industries such as cabinets, elevator door panels, hardware home appliances, and automotive parts, providing reliable support for welding needs in various scenarios.

Purchase Invitation

If you are also facing welding challenges such as "the need for grinding after welding, difficulty in matching multiple materials, and poor precision for large - size workpieces," whether you are producing cabinet shells, precision components, or large - size metal workpieces, feel free to contact Guangdong PDKJ Automation Technology Co., Ltd. - - with a professional technical team, high - quality welding equipment, and a comprehensive service system, we will provide you with the most suitable welding solutions. Let PDKJ become your reliable partner in welding, jointly tackle welding challenges, enhance product quality and production efficiency, and boost the development of your enterprise. PDKJ, your welding expert, looks forward to cooperating with you!

WhatsApp

WeChat

If you have welding machine requirements, please contact Ms. Zhao

E-Mail: pdkj@gd-pw.com

Phone: +86-13631765713